Sanitary valves are vital components in pharmaceutical and bioprocess systems, engineered to provide leak-free flow control while maintaining hygienic integrity. Fabricated from high-grade stainless steel (commonly 316L), with minimal dead-legs, polished internals and CIP/SIP compatibility, these valves help prevent contamination, bio-fouling and product loss. Common types include ball, butterfly, diaphragm and check valves, each tailored for applications such as buffer transfer, WFI loops, product filling, venting and tank bottom discharge. Selecting the right valve means considering port size, actuation method (manual, pneumatic or electric), finish specification (e.g., Ra ≤ 0.5 µm), connection type and pressure/temperature ratings. Properly specified sanitary valves enhance process reliability, support regulatory compliance and ensure long-term cleanliness in critical fluid systems.

Sanitary Valves

Showing 1–24 of 72 results

-

Sanitary Valves

1.5 Inch Tri Clamp Sanitary Butterfly Valve with Pull Handle Stainless Steel 304 Tri Clamp Clover (1.5″ Tri Clamp Butterfly Valve)

Sanitary Valves

Sanitary Valves1.5 Inch Tri Clamp Sanitary Butterfly Valve with Pull Handle Stainless Steel 304 Tri Clamp Clover (1.5″ Tri Clamp Butterfly Valve)

The 304 stainless steel of the sanitary butterfly valve makes the valve with high toughness and high hardness. Besides, our butterfly valve has passed the 100% pressure hydraulic reliability test, with a rubber ring inside to ensure the sealing, so the liquid is not easy to leak.

The rotary handle of the stainless butterfly valve can meet the needs of locking three different valves positions. Different valves positions have different flow rates. You only need to turn the handle. The nylon sleeve on the handle can reduce friction and make the rotation more smooth.

SKU: n/a -

Sanitary Valves

1.5” SS304 Stainless Sampling Valve Beer Sampling Valve Clamp End, 2 Pack

- Made of food‑grade 304 stainless steel, durable in use, wear‑resistant, and anti‑aging

- Seat Seal: Silicon; Sample Valves Bonnet knob 1.5″ TC

- Pressure Rating 150 P. S. I.G; With lip for pigtail hook up

- Equipped with a comfortable hand-wheel

- Easy to install, smooth rotation and low fluid resistance

SKU: n/a -

Accessories & Supplies, Sanitary Valves

1.5″ Medical breathing valve PVRV sanitary plunger valve stainless steel regulating breathing valve

Accessories & Supplies, Sanitary Valves

Accessories & Supplies, Sanitary Valves1.5″ Medical breathing valve PVRV sanitary plunger valve stainless steel regulating breathing valve

The valve is used in pressure vessel piping system. The breathing valve has two functions. When the pressure is higher than the set pressure (standard 1BAR), it can exhaust, otherwise it is closed. When a vacuum (standard -0.2BAR) is generated in the pipeline system, the valve will automatically open to ensure the safety protection of equipment and related instruments, and it can also meet the needs of various production processes.

The valve is made of stainless steel and has a hygienic design, which is suitable for various industrial fields such as food processing, beer, beverage and pharmaceuticals.

SKU: n/a -

Accessories & Supplies, Sanitary Valves

1.5″ Sanitary quick-loading sampling valve stainless steel beer tank sampling valve

Accessories & Supplies, Sanitary Valves

Accessories & Supplies, Sanitary Valves1.5″ Sanitary quick-loading sampling valve stainless steel beer tank sampling valve

- Made of high quality304 stainless steel, this sampling valve is durable

- Simple structure, beautiful shape, quick to install and uninstall, flexible operation

- The fluid resistance is small, safe and reliable to use

- Standard design, the sampling valve is composed of three parts, valve, handle and diaphragm.Rubber diaphragm on the valve stem works as a tensile plug

- Widely used for beer, chemical, petroleum, metallurgy, water heating, etc

SKU: n/a -

Accessories & Supplies, Sanitary Valves

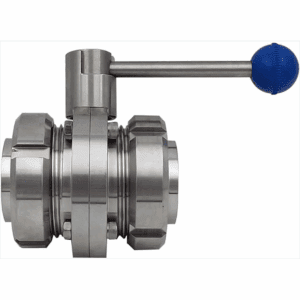

1.5″ Tri Clamp Sanitary ball Valve,3 way Tee ball Valve T Port,PTFE Lined and Triclamp Triclover with 3 pcs silicone gasket

Accessories & Supplies, Sanitary Valves

Accessories & Supplies, Sanitary Valves1.5″ Tri Clamp Sanitary ball Valve,3 way Tee ball Valve T Port,PTFE Lined and Triclamp Triclover with 3 pcs silicone gasket

Specification:

Material: Stainless steel 304

Handle: Blue Vinyl Handle to Clamp Ferrule

Seal: Silicone

Operating Temperature : 15º F to 200º F

Pressure:1.6MPASKU: B07PZ3CZRP -

Accessories & Supplies, Sanitary Valves

1.5″ Tri-Clamp Ball Valve 2PCS Stainless Steel 304 PTFE Lined

Accessories & Supplies, Sanitary Valves

Accessories & Supplies, Sanitary Valves1.5″ Tri-Clamp Ball Valve 2PCS Stainless Steel 304 PTFE Lined

Seats & Seals

The seat of this stainless steel ball valve is 2-pieces, and the seal is made of PTFE. It offers unobstructed and maximum flow.Available Size

Connection Type:1.5 inch Tri Clamp Tube OD:1 inch

Connection Type:1.5 inch Tri Clamp Tube OD:1.5 inch

Connection Type:2 inch Tri Clamp Tube OD:2 inchApplication

Chemical, Hydraulic, Dry/Liquid Chlorine, Food Processing, Oxygen, Steam, Thermal Fluids, Vacuum, Water/Oil/Gas.SKU: n/a -

Sanitary Valves

2 Inch Tri Clamp Sanitary Butterfly Valve with Pull Handle Stainless Steel 304 Tri Clamp Clover (2″ Tri Clamp Butterfly Valve)

Sanitary Valves

Sanitary Valves2 Inch Tri Clamp Sanitary Butterfly Valve with Pull Handle Stainless Steel 304 Tri Clamp Clover (2″ Tri Clamp Butterfly Valve)

Our tri clamp butterfly valve can withstand 15 °F to 200 °F temperature, so don’t worry about melting at high temperature. At the same time, it is equipped with stronger pressure resistance and higher adaptability, which can hold 1.6mp maximum pressure.

Our food-grade sanitary butterfly valve can be used to control the flow of various fluids and is suitable for stainless steel piping system in food and beverage, dairy, wine-making, chemical, and other industries.

SKU: n/a -

Accessories & Supplies, Sanitary Valves

2” Breathing Valve Sanitary Stainless Steel Breathing Valve Quick Install Breathing Valve for Medicine

Accessories & Supplies, Sanitary Valves

Accessories & Supplies, Sanitary Valves2” Breathing Valve Sanitary Stainless Steel Breathing Valve Quick Install Breathing Valve for Medicine

The valve is used in pressure vessel piping systems.

Breathing valve has two functions, when the pressure is higher than the set pressure (standard 1 BAR) can exhaust, whereas closed, while vacuum piping system (standard -0. 2BAR) when the valve opens automatically, to ensure the safety of the equipment and related instrumentation protection, at the same time can also meet the demand in all kinds of production process, the valve in stainess steel material, health design, content with all sorts of food processing, beer, beverage and pharmaceutical and other industries.

SKU: n/a -

Sanitary Valves

3/4″ Sanitary Ball Valve Fits 1.5″ Tri-Clamp Clover Stainless Steel 304, PTFE Lined , Two Way & Three Piece (3/4 Inch Tube OD Quick Clamp)

Sanitary Valves

Sanitary Valves3/4″ Sanitary Ball Valve Fits 1.5″ Tri-Clamp Clover Stainless Steel 304, PTFE Lined , Two Way & Three Piece (3/4 Inch Tube OD Quick Clamp)

【 Sanitary Ball Valve Material and Function 】Sanitary Ball Valve is made of FOOD GRADE LEVEL MATERIAL stainless steel 304 which have high strength and great corrosion resistance

【 Sanitary Ball Valve Advantage 】Quick clamp connection for disassembling and cleaning in place

【 Great Design 】Non-Retention Sanitary Ball: 2-Way & 3-Piece Contruction, Lockable oval handle for manual on/off control

SKU: n/a -

Sanitary Valves

304 stainless steel pneumatic valve/sanitary pneumatic butterfly valve

Product features:

1. The shape is exquisite and beautiful, and the overall inner and outer surface is mirror polished.

2. Corrosion-resistant, using SS304/316L stainless steel

3. Strong versatility, quick installation connection method, more convenient and fast installation

SKU: n/a -

Sanitary Valves

316 quick-release butterfly valve sanitary stainless steel clamp type quick-release manual butterfly valve

Sanitary Valves

Sanitary Valves316 quick-release butterfly valve sanitary stainless steel clamp type quick-release manual butterfly valve

P-grade manual welding butterfly valve is suitable for dairy products, food, pharmaceutical, beer, cosmetics, etc.

1. Name: butterfly valve, stainless steel quick-loading butterfly valve, food-grade butterfly valve, sanitary manual quick-loading butterfly valve, stainless steel, acetic acid-resistant quick-loading butterfly valve 2. Packaging: carton/wooden box, sanitary manual quick-loading butterfly valve

3. Connection: quick installation

4. Material: SUS304.

SUS316L, forged

5. Specifications: DIN standard: DN15 a DN100; ISO standard: Medium 19 (0.75s)–medium 108 (4.25s)SKU: n/a -

Sanitary Valves

4″ Tube Outer Diameter Tri Clamp Butterfly Valve 304 Stainless Steel with Pull Handle for Controlling the Fluid

Sanitary Valves

Sanitary Valves4″ Tube Outer Diameter Tri Clamp Butterfly Valve 304 Stainless Steel with Pull Handle for Controlling the Fluid

The food-grade sanitary butterfly valve can be effectively used for fluid control in food manufacturing, dairy products, and wine-making process. Its 304 stainless steel and butterfly plate design can ensure airtightness. High temperature and high-pressure resistance make the product have higher applicability. Pull handle saves your effort during operation.

SKU: n/a -

Accessories & Supplies, Sanitary Valves

Beer fermentation tank regulating valve Precision pressure regulating water seal valve Sanitary safety valve Stainless steel liquid seal valve

Accessories & Supplies, Sanitary Valves

Accessories & Supplies, Sanitary ValvesBeer fermentation tank regulating valve Precision pressure regulating water seal valve Sanitary safety valve Stainless steel liquid seal valve

The valve is used in pressure vessel piping system . Adjust the one-way exhaust valve to protect the container from excessively high pressure. It can be exhausted when the pressure is higher than the set pressure (standard 1BAR). It is easy to use, accurate in scale, and can also meet the needs of various production processes. It is suitable for various industrial fields such as food processing, beer, beverage, and pharmaceuticals.

SKU: n/a -

Sanitary Valves

Butterfly Valve with Blue Trigger Handle Stainless Steel 304 Tri Clamp Clover (1.5 inch Tri Clamp Butterfly Valve)

Sanitary Valves

Sanitary ValvesButterfly Valve with Blue Trigger Handle Stainless Steel 304 Tri Clamp Clover (1.5 inch Tri Clamp Butterfly Valve)

- Tube OD: 1-1/2 Inch, Ferrule Size: 50.5MM, Fits 1.5 Inch Tri-clamp

- Trigger style handle butterfly valve – 13 Positions

- Temperature Rating (spec): 15°F thru 200°F; Material (spec): 304 Stainless Steel

- Tri-Clamp butterfly valve Max Pressure 1.6MPA, 100 Percent pressure hydraulic tested for reliability

- The Trigger style handle allows you to set the valve in four different positions simply by pulling and turning

SKU: n/a