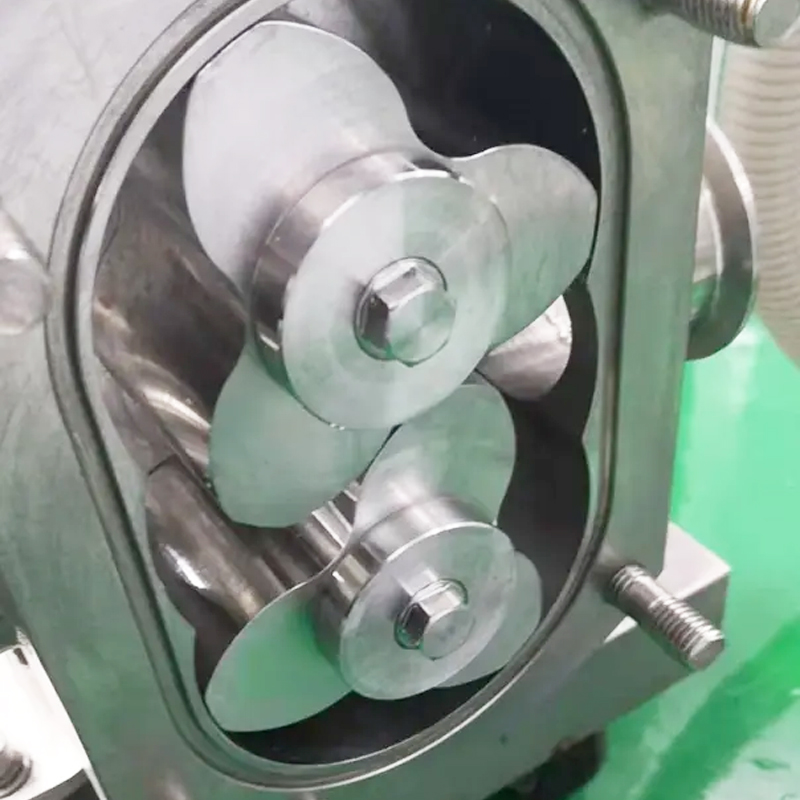

Sanitary stainless steel high viscosity rotor lobe pump syrup molasses honey transfer pump

Ransmission Section Selection:

● Motor + Fixed Ratio Reducer: this method of transmission is simple, the rotor speed is constant,

which also determines the flow rate is not adjustable.

● Motor + Mechanical Friction Type Stepless Transmission: this type of transmission is manually adjusted to achieve variable speed. It is characterized by safe and reliable, large torque, flow adjustable stepless. Disadvantages are non-automatic adjustment and more troublesome. The speed must be adjusted in the working process, and it must not be adjusted under stop state. Please refer to the manufacturer’s instructions for use and maintenance

specifications.

● Converter Motor + Converter: the speed can be automatically adjusted in this way, which means that the flow can

be adjusted steplessly. The advantage is that the degree of automation is high and the low speed torque is large; the disadvantage is that the price of the inverter is relatively high. Please refer to the manufacturer’s instruction manual for maintenance specifications.

$385.00

Compare

The flow range in the table refers to the data measured when the medium is “water”.

There are no reviews yet.