Plastic Recycling Granulator Machine PET ABS Plastic Granules Pellet Crusher Soundproof Plastic Crusher with Collector

NOTE: Prices may vary by product model and material.

- The Soundproof Plastic Granulator is a specially designed equipment for shredding various plastic products, runner and edge materials.

- It incorporates noise reduction technology to minimize noise pollution.

- By implementing noise reduction measures, the Centralized Silent Plastic Granulator significantly reduces the noise level during the plastic shredding process, providing a quieter working environment and reducing noise interference for workers and the surrounding environment.

- This type of crusher is widely used in the plastic recycling and processing industry, contributing to improving working conditions and reducing noise pollution.

$1,650.00

CompareMODELS OF THE Plastic Recycling Granulator Machine

| Model | GP400-SP | GP500-SP | GP600-SP | GP800-SP |

| Grinding Chamber | 410×240mm | 510×300mm | 610×330mm | 815×470mm |

| Grinding Capacity | 200-250KG/H | 300-350KG/H | 350-450KG/H | 450-600KG/H |

| Stationary Cutter | 2 | 2 | 4 | 4 |

| Rotary Cutter | 12 | 15 | 18 | 24 |

| Mesh Size | Ф8mm | Ф10mm | Ф10mm | Ф10mm |

| Power | 7.5KW | 11KW | 15KW | 22KW |

| 10HP | 15HP | 20HP | 30HP | |

| Dimension (L×W×H) | 1350×930×1590mm | 1560×1070×1784mm | 1560×1170×1870mm | 1900×1510×2460mm |

| Net Weight | 604KG | 1220KG | 1420KG | 2380KG |

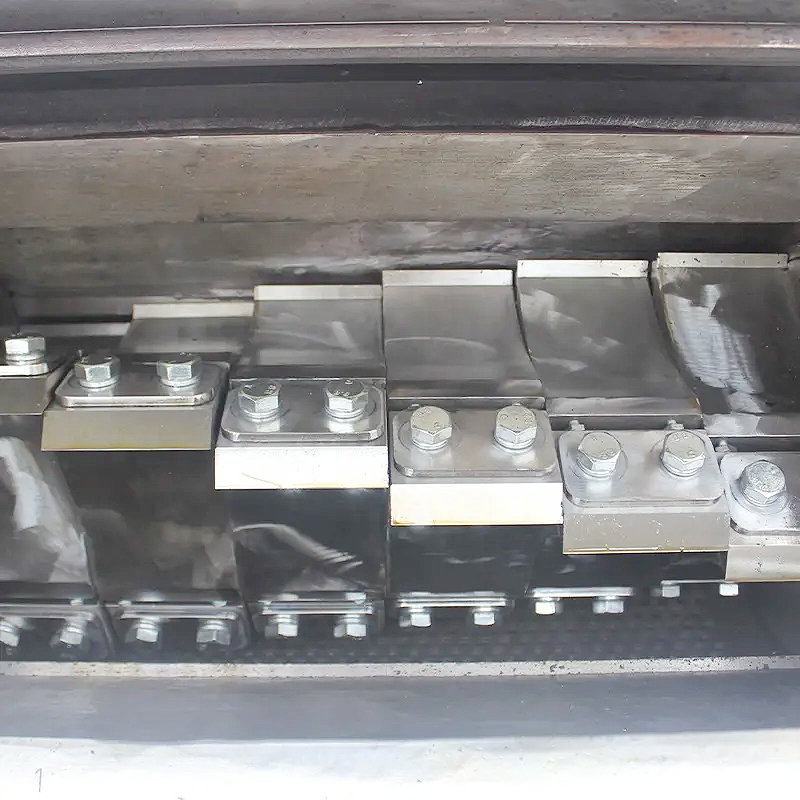

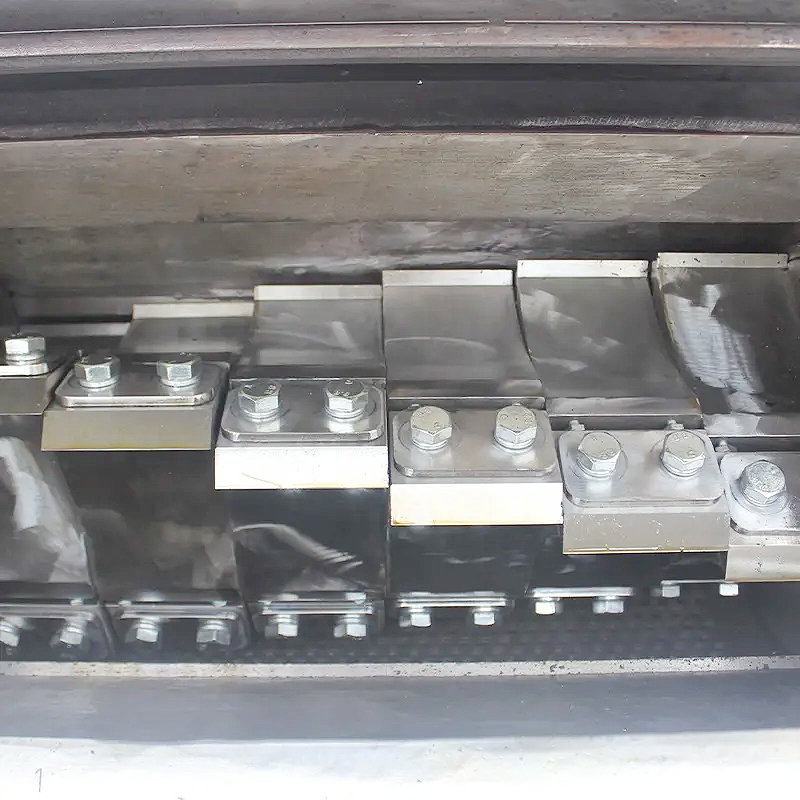

High-strength cutting tools

The main shaft knife holders are made of 45# steel that has been quenched and tempered.

CR12MOV blades are used, which have a hardness of 57-59 degrees.

Safety & Stability

The entire line of crushers is equipped with Siemens electronic components to ensure equipment performance stability.

Additional safety protection devices, such as current relays, motor overload protection, and phase sequence protection, are installed to enhance safety measures.

Stainless steel Layer

The inner layer of the crusher is made of stainless steel material to prevent paint peeling and contamination of the raw materials caused by high-speed impacts during the crushing process.

Feeding System

The crusher is equipped with a standard feeding system that eliminates the need for manual feeding. It automatically recycles and reuses the materials, significantly improving production efficiency.

There are no reviews yet.