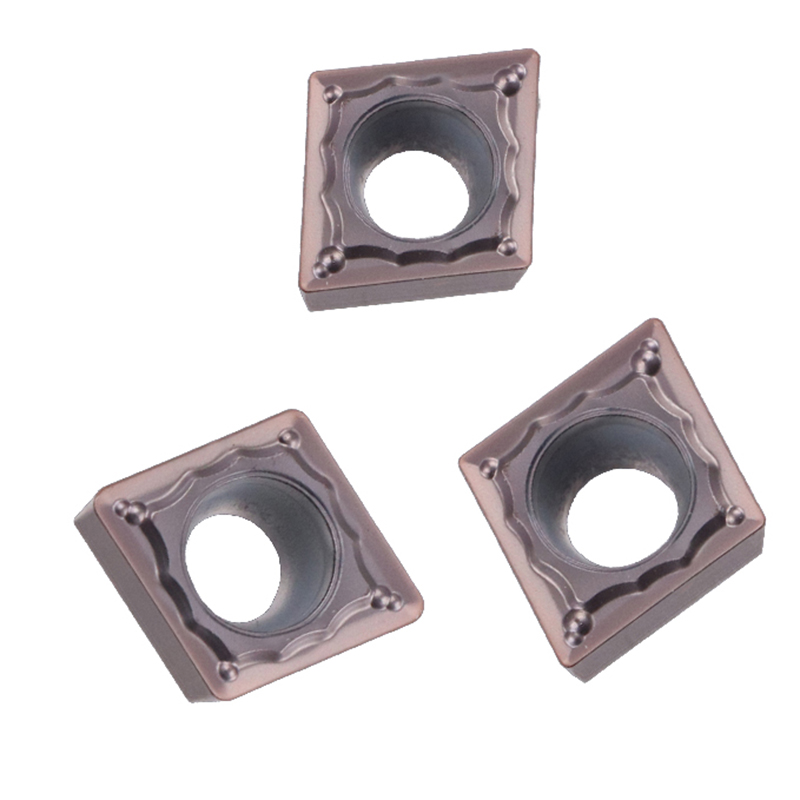

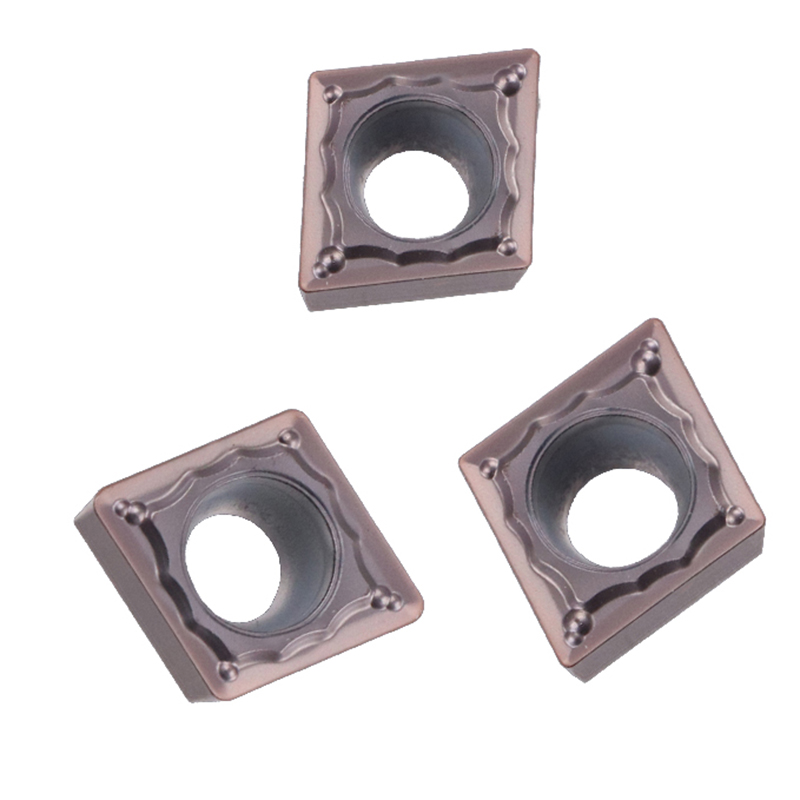

CNC blade diamond CCMT09T304 lathe stainless steel inner hole knife grain boring alloy blade

CCMT09T302-GE

Material: WS3315 finishing

Processing hardness HRC2545

It can process GH1140 nickel-iron, GH145.GH98, K2 superalloy plate, stainless steel 304, 316, etc.

suitable for continuous processing

$3.00

Compare1. The diamond-shaped blade is sharp in cutting, low in cutting resistance, and will not cause deformation of the workpiece, especially suitable for processing thin-walled parts and slender shafts, and suitable for continuous cutting

2. Groove characteristics: for ordinary steel, alloy steel, and stainless steel finishing. The cutting edge is sharp and the surface finish is high. The gourd island-shaped boss on the rake face can effectively control chips under the condition of small depth of cut and small feed. Suitable for intermittent and continuous cutting

3. Material characteristics: High wear resistance is achieved by combining the substrate with strong anti-deformation ability and PVD TIAIN coating. When the depth of cut is 0.5-2MM, the SF geometry can achieve good chip breaking, chip removal, and stable control of chip flow direction

4. Processing hardness: below HRC45 degrees

Based on 0 reviews

Be the first to review “CNC blade diamond CCMT09T304 lathe stainless steel inner hole knife grain boring alloy blade” Cancel reply

Related products

-

CNC Machines, Metal Machine Tool Industry

CUT70 new plasma cutting machine,110/220 dual power supply

0 out of 5(0)1. Wide current adjustment range, excellent adjustment characteristics, suitable for cutting carbon steel, stainless steel and other non-ferrous metals:

2. Double module design, high reliability;

3. Non-contact high-frequency arc ignition, high arc ignition success, stable transfer arc ignition, and low interference; 4. Fast cutting speed, small deformation, twice the speed of traditional oxygen acetyleneSKU: n/a$1,198.00 -

Indexable Cutting Tools, Metal Machine Tool Industry

1pcs MCLNR1616H12 indexable carbide turning tool holder and 5 pcs CNMG120404 carbide inserts, lathe cutting tools (MCLNR1616H12 + 5 pieces CNMG 431)

Indexable Cutting Tools, Metal Machine Tool Industry

Indexable Cutting Tools, Metal Machine Tool Industry1pcs MCLNR1616H12 indexable carbide turning tool holder and 5 pcs CNMG120404 carbide inserts, lathe cutting tools (MCLNR1616H12 + 5 pieces CNMG 431)

0 out of 5(0)- Models: 5/8″ MCLNR1616H12 and 5pcs CNMG120404 (CNMG 431)

- Shank(length×width): ( 5/8″x5/8″ inch / 16*16mm),Overall Length:( 3.94″ / 100mm) , Cutting Direction:right hand

- The Holder is black oxidized smooth surface and Tool Hardness, Turning inserts exquisite workmanship, High Strength, High Toughness, Stable and Durable.

- Package : 1pcs 5/8″ MCLNR1616H12 Holder + 5pcs CNMG120404 (CNMG 431) Carbide Inserts

SKU: n/a$60.00 -

Indexable Cutting Tools, Metal Machine Tool Industry

5 Piece 3/8″ Mini Lathe Indexable Carbide Insert Tool Bit Set

Indexable Cutting Tools, Metal Machine Tool Industry

Indexable Cutting Tools, Metal Machine Tool Industry5 Piece 3/8″ Mini Lathe Indexable Carbide Insert Tool Bit Set

0 out of 5(0)- Includes 5 inserts

- 2 pieces style “A” for turning, facing, boring, and chamfering

- 2 pieces style “B” for turning, facing, boring, and for lead angles

- 1 piece style “E” for turning, facing, boring, chamfering, threading, and V-grooving

- Hex wrench and 3 replacement hold-down screws

SKU: n/a$76.00 -

Indexable Cutting Tools, Metal Machine Tool Industry

Lathe Turning Tool with Wrench, 10PCS DCMT070204 US735 DCMT21.51 CNC Coated Carbide Insert Blade Lathe

Indexable Cutting Tools, Metal Machine Tool Industry

Indexable Cutting Tools, Metal Machine Tool IndustryLathe Turning Tool with Wrench, 10PCS DCMT070204 US735 DCMT21.51 CNC Coated Carbide Insert Blade Lathe

0 out of 5(0)- 【Convenience】Suitable for cutting common steel, convenient to use.

- 【Durable】Good cutting effect, reducing cutting force and improving tool life.

- 【Safety】The blade is safe and good toughness, safe and durable to use.

- 【High Hardness】It is a quality built product,Made of high quality carbide, high hardness, solid and durable to use.

- 【High Quality】100% brand new and high quality. Carbide-PVD composite coating for semi-finishing of steel.

SKU: n/a$58.00

There are no reviews yet.