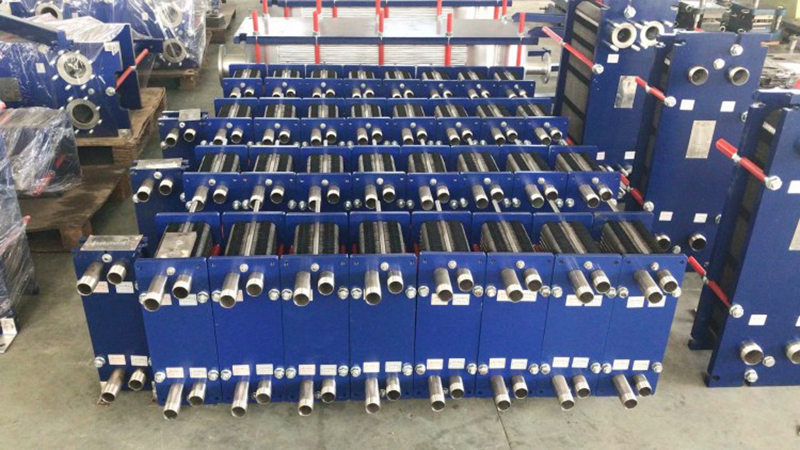

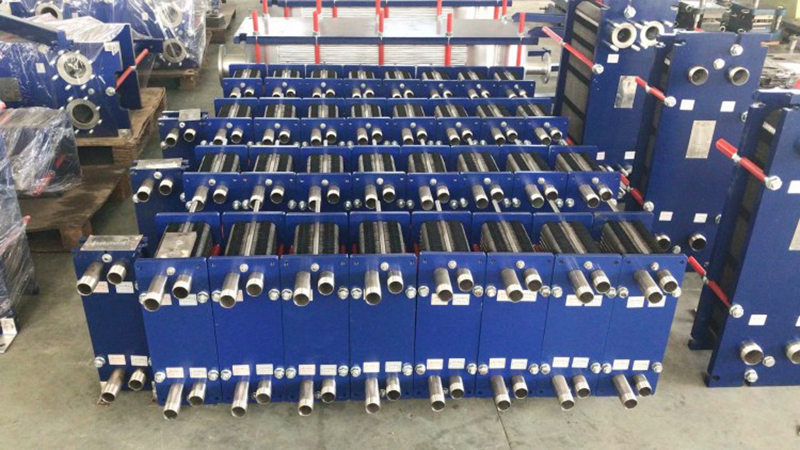

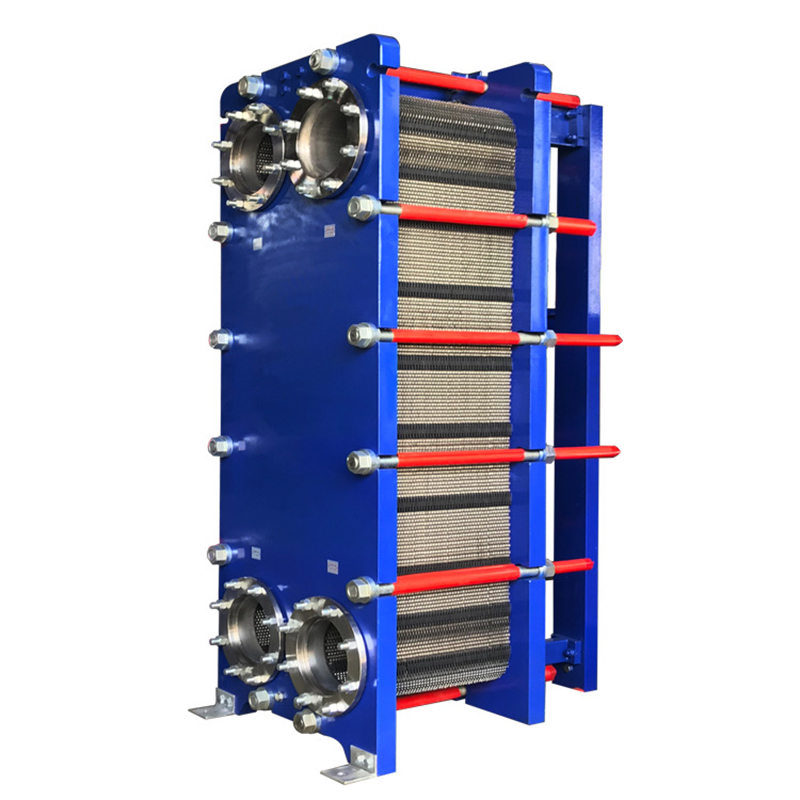

Sanitary Plate Heat Exchanger PHE Heat Exchanger 2 stage 10 sq. meter

Plate heat exchanger. All sizes can be delivered with one or two stages.

The model with one stage is primarily designed for cooling with tap water.

The model with two stages are cooling with tap water in one zone and glycol from cooling system in the other zone.

Heated tap water can be reused for brewing. Different size depending on demand.

$5,999.00

ComparePlate heat exchanger. All sizes can be delivered with one or two stages.

The model with one stage is primarily designed for cooling with tap water.

The model with two stages are cooling with tap water in one zone and glycol from cooling system in the other zone.

Heated tap water can be reused for brewing. Different size depending on demand.

What are plate heat exchangers?

Plate heat exchangers are one of the most common types of heat exchanger employed today.

Plate heat exchangers have gained widespread application throughout the engineering world because they are efficient, robust, and relatively easy to maintain.

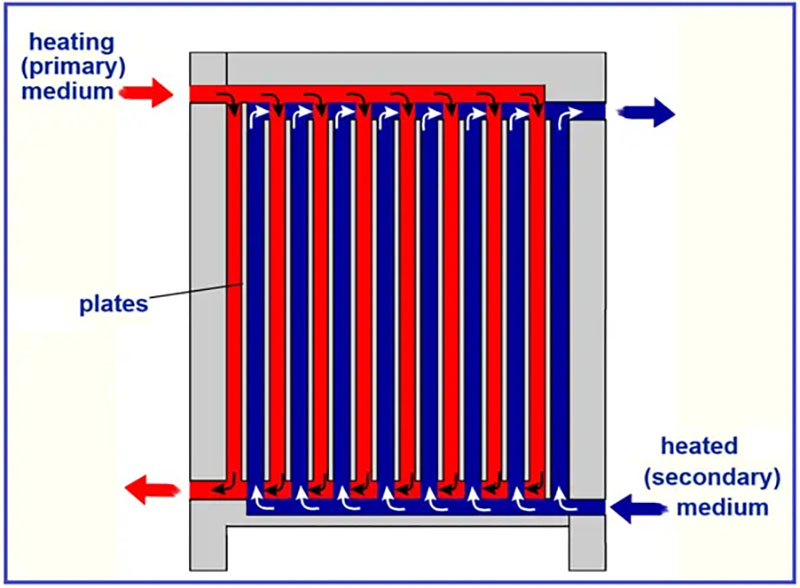

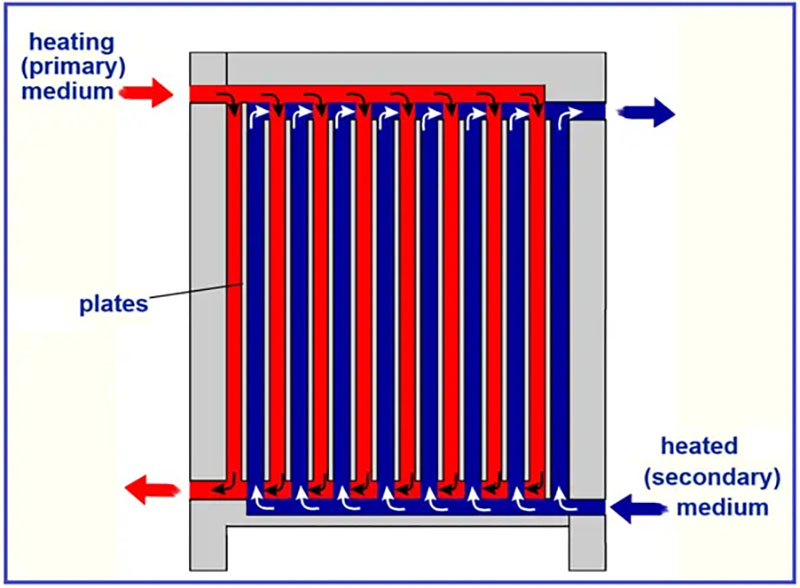

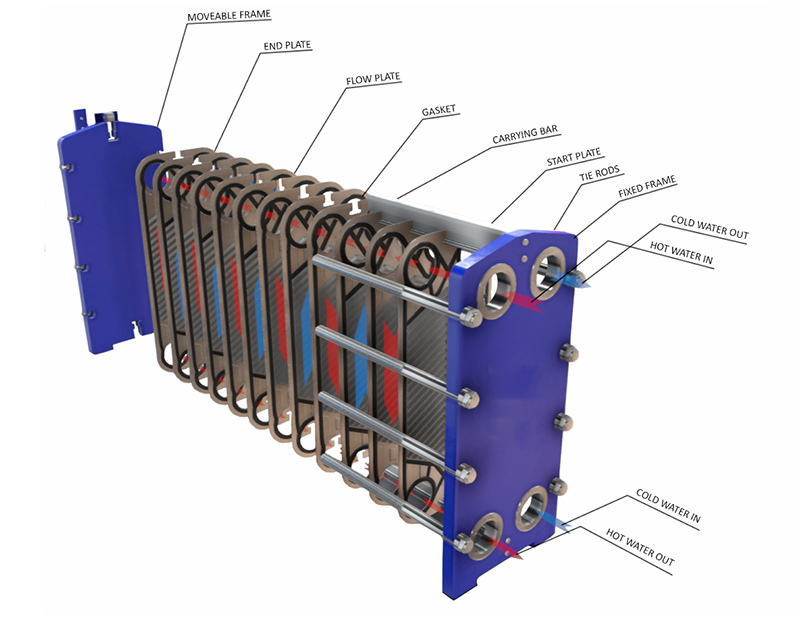

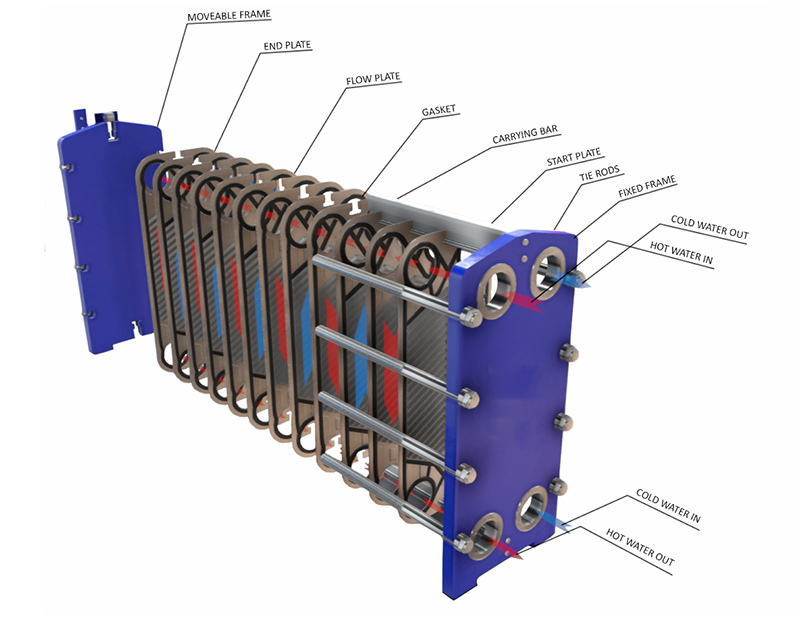

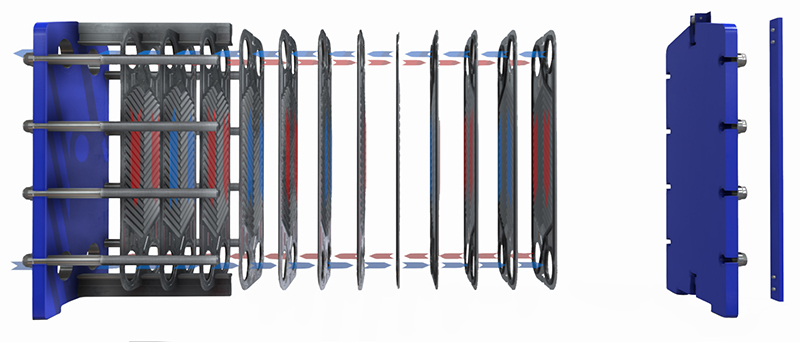

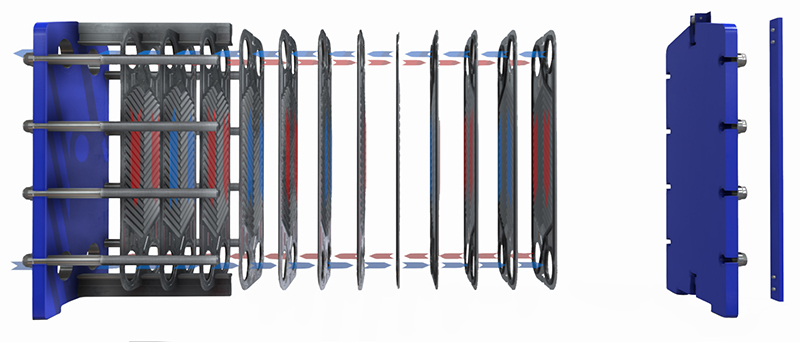

Plate heat exchangers consist of relatively few parts. Because plate heat exchangers are used for transferring heat, they require inlets and outlets where the flowing mediums -or fluids- can enter and leave the heat exchanger. A fluid may be a liquid or a gas. As fluids are often assumed to be liquid only, we will use the term flowing medium to avoid confusion.

Gaskets and plates are used to separate the flowing mediums and prevent them mixing; gaskets are adhered to one side of each plate only. The plates hang upon a carry bar and are pressed together using clamping bolts. When the plates are compressed together, they are referred to as a ‘plate stack’. A guide bar ensures the plates are aligned correctly when the plate stack is opened and closed.

The final components of interest are the two covers at opposite ends of the plate stack. One cover is movable whilst the other is fixed. The movable cover and fixed cover are also sometimes referred to as the frame plate and pressure plate. Note that the inlets and outlets are mounted to the fixed cover only.

Description

• 304 stainless steel, Clip-on gasket material EPDM

• Maximum pressure 10 bar

• Max. temperature: 250 F.

• Fixed bolted head, easy for inspection or CIP

Plate selection

| Sheet material | Suitable for fluid |

| stainless steel 304/316L | Purified water, river water, cooking oil, mineral oil |

| Ti,Ti-Pd | sea water, salt water, salinity |

| 254 alloy 20Cr,18Ni,SMO | Dilute sulfuric acid, dilute sulfide aqueous solution, inorganic aqueous solution |

| Ni | High temperature, high concentration caustic soda |

Gasket selection

| Gasket Material | Operating Temperature | Suitable Fluid |

| Nitrile rubber NBR | -15 to +135 | Water, sea water, mineral oil, salt water |

| EPDM | -25 to +180 | hot water, steam, acid, alkali |

| Viton | -55 to +230 | acid, alkali, fluid |

There are no reviews yet.