Marine & Industrial Use – Heat Exchangers & Coolers

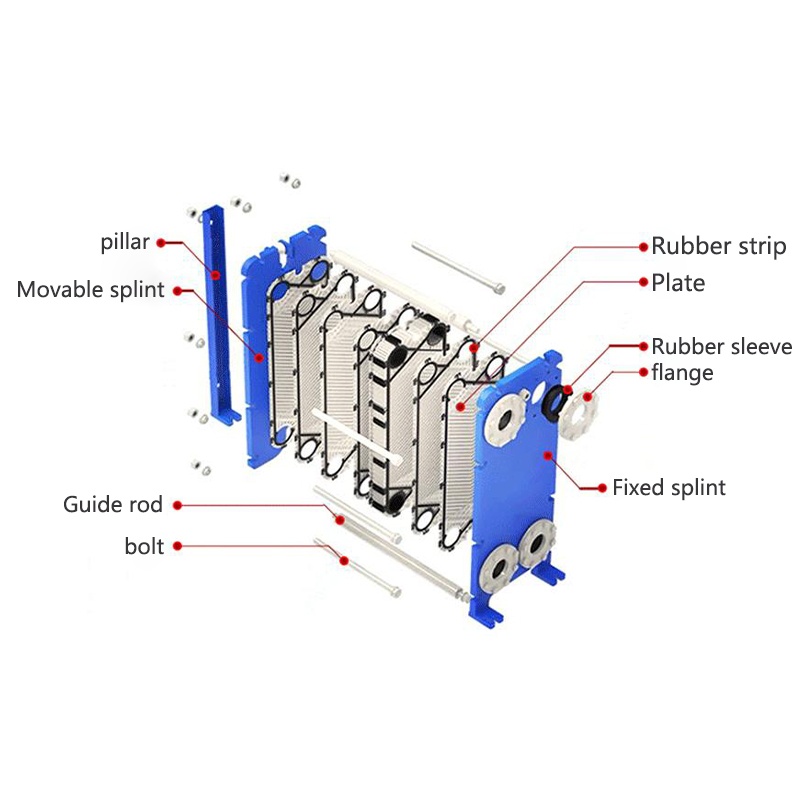

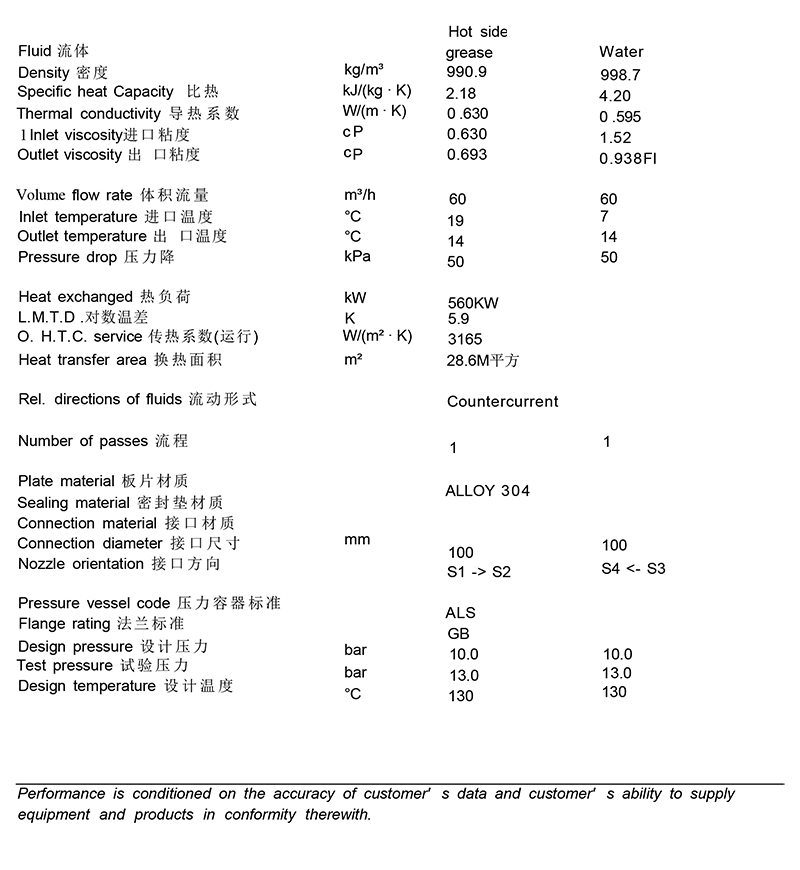

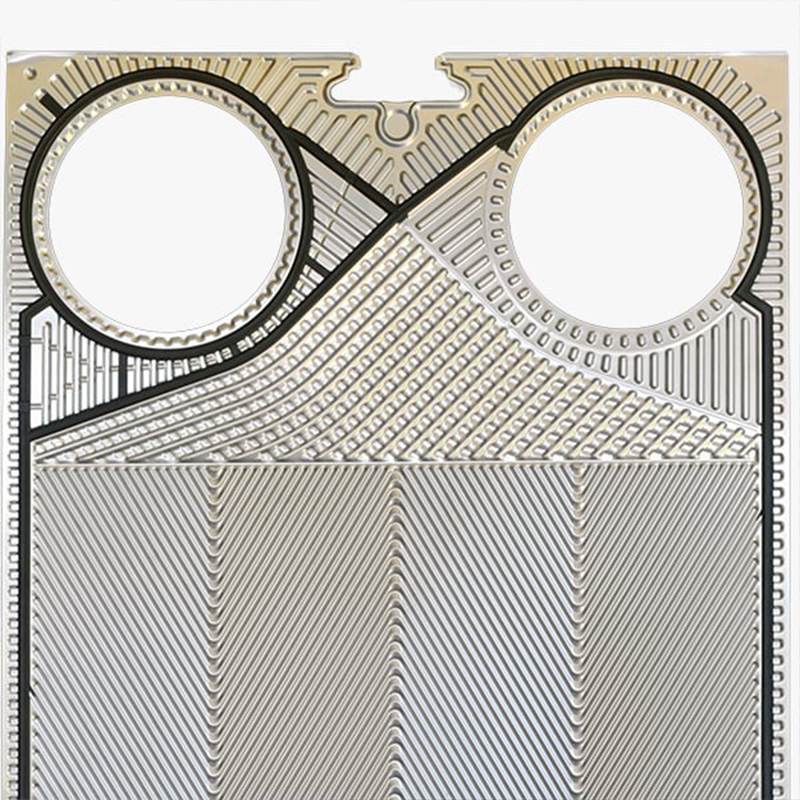

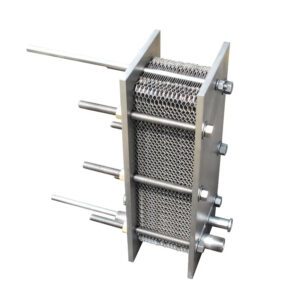

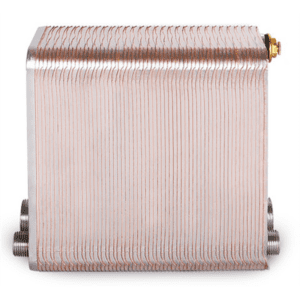

Plate heat exchanger is a relatively efficient heat exchanger made of corrugated metal sheets stacked together. It has efficient heat transfer efficiency and is a heat transfer equipment with high heat transfer efficiency, low heat loss and wide application in heat exchangers.According to the different structures of plate heat exchangers, they can be divided into detachable plate heat exchangers, welded plate heat exchangers, spiral plate heat exchangers, and plate-coil heat exchangers.

$3,055.00

CompareTEMPERATURE APPROACHES

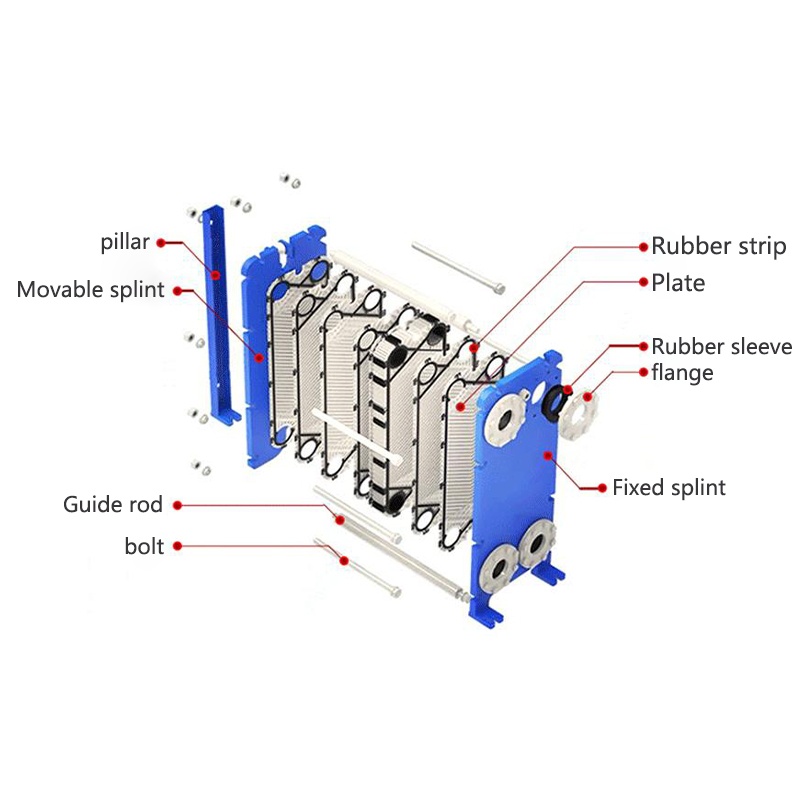

Of less than 1°C (2°F), with “U” or “K “ values 3 to 6 times higher than shell and tube exchangers

EASY ACCESSIBILITY

Opens within its own footprint simply by loosening the tie-rod bolts and rolling the movable frame back to the support column

MAXIMUM FLUID COMPATIBILITY

Range of alloys, including titanium, plus variety of gasket elastomer compounds, to precisely match your fluid characteristics for maximum uptime

INDUCED TURBULENCE

Promotes maximum heat transfer; induces scouring action that fights fouling or scaling

REDUCED FOOTPRINT

Fits into 20–50% of a shell and tube footprint including service and maintenance space. And, it costs less

HIGHLY VERSATILE

Hundreds of plate styles, patterns and draw depths to precisely match your application requirements

RELATED PLATE & FRAME APPLICATIONS

- Heat exchanger duties wherever operating temperatures and pressures do not exceed 180°C (356°F) or 27.5 bar (400 psi)

- Space-limited process expansions

- HVAC

- Heat recovery from low grade waste streams

- Viscous fluids or slurries

- Industrial fluids suitable for high heat transfer rates at low pressure drops

RELATED PLATE & FRAME SERVICES

- Technical specialists at Tranter Service Centers have factory trained experience and know-how

- Providing heat exchanger service for all brands of plate and frame heat exchangers in our shops or in your facility

- Safe inspection and cleaning of plate and frame heat exchangers and gasket and plate replacement services, returning units to OEM condition and efficiency

- All work guaranteed by written warranties covering materials and workmanship

| brand | Ndpac |

|---|---|

| Heating method | central heating |

| Place of origin | Mainland China |

There are no reviews yet.