Pressure Transmitters

Juice Pressure Transmitter Flat Membrane Pressure Transmitter Anti-clogging Diaphragm Gel Press Pressure Transducer IP65 SS316/304

- Powerful anti-interference chip, high precision, fast response.

- Almighty circuit board can intelligently calibrate pressure and temperature compensation to ensure accurate linearity.

- Hessmann connector, more reliable contact, convenient wiring.

- Premium quality upgraded leads. The material is anti-interference and aging-resistant, and a 2-meter lead wire is provided for free. (can be customized to extend)

NOTE: Prices may vary by product model and material.

$155.00

CompareProduction process of pressure transmitter

- Component screening: A good pressure transmitter starts with components. From screening test to qualified employment, we check at every level to provide you with high-quality pressure transmitters.

- 6 times accuracy standard: Germany General Electric automatic calibration system is adopted. Each product has been accurately calibrated 6 times from production to delivery. Three-point detection of zero point, mid-point and full scale covers the full range, and the measurement accuracy is much higher than that of two-point calibration.

- High-temperature aging detection: high-temperature detection, aging detection, core body detection, component detection, finished product detection, and out-of-warehouse detection. Each pressure transmitter has undergone a 48-hour high temperature test. Nearly ten testing procedures ensure that each pressure transmitter is durable.

- Laser marking: Each pressure transmitter has a corresponding “identity number”. From production to testing, digital management.

| Range | -100KPA…0~10KPA…60MPA | ||||

| Overload pressure | 1.5 times the rated pressure | ||||

| Accuracy | ±0.5%F.S/±1.0%F.S | ||||

| Stability | <0.5%F.S/year | ||||

| Working temperature | -20~+85°C | ||||

| Storage temperature | -40~+100°C | ||||

| Measured medium | Gas or liquid compatible with 304 and 316L stainless steel, fluorine rubber or nitrile rubber | ||||

| Electrical performance | Two-wire | Three-wire | Three-wire | Three-wire | Four-wire |

| Output signal | 4-20mA | 0.5-4.5V | 0-5V | 0-10V | RS485 |

| Power supply | 10-30VDC | 4.75-5.25VDC | 10-30VDC | 12-30VDC | 10-30VDC |

| Shell protection grade | IP67, IP54 | ||||

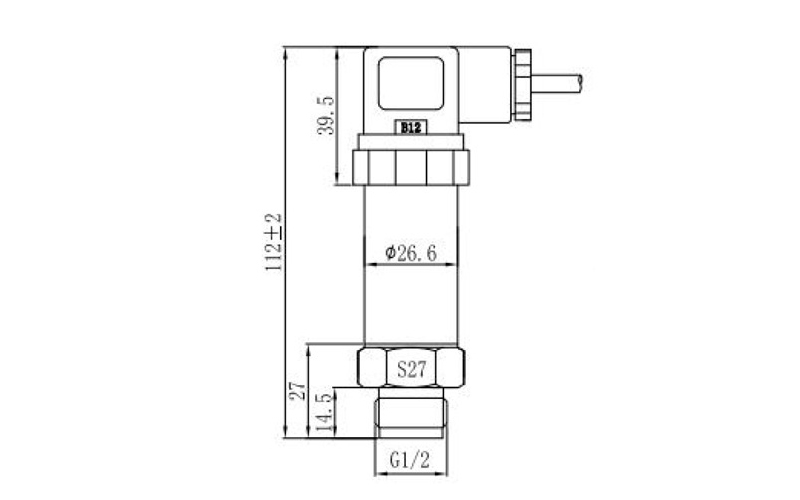

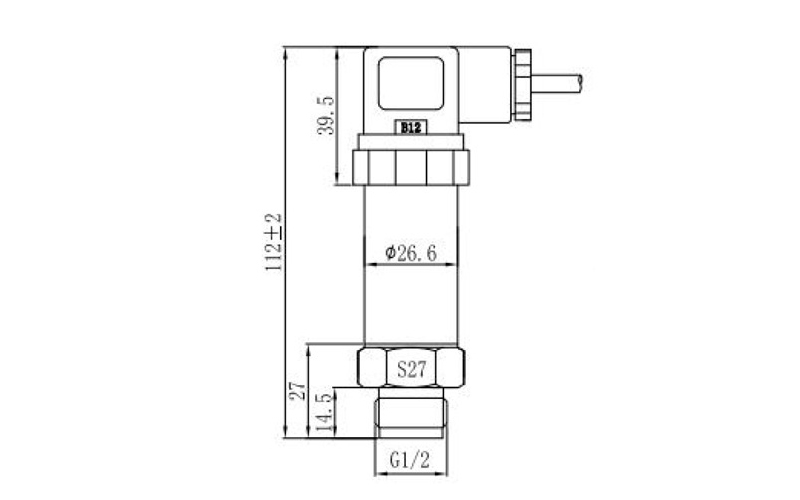

| Pressure port | M20*1.5, G1/2 | ||||

There are no reviews yet.