Threading Tools

HSS6542 Machine Taps for Stainless Steel Iron Aluminum Copper Flute / Straight Flute / Tip Machine Taps Threading Tools

NOTE: Prices may vary by product model and material.

MOQ: 10pcs

- Product Name: Machine Tap

- Material: 6542 HSS

- Applicable: suitable for processing stainless steel, iron, aluminum, copper, steel (*cold-rolled steel: steel without heat treatment) and other metal materials with high hardness

- Features: smooth surface, full grinding process, sharp knife edge, durable

- Note: Machine taps have high requirements on concentricity, and manual tapping is prohibited

$4.20

CompareModels of the HSS6542 Machine Taps

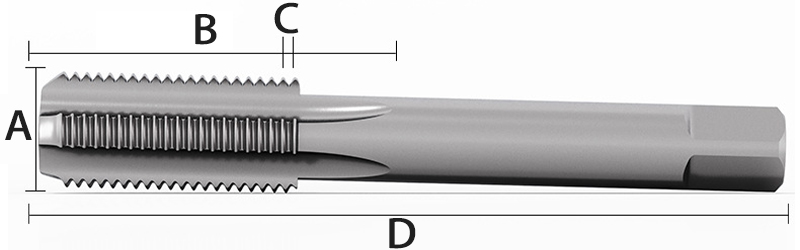

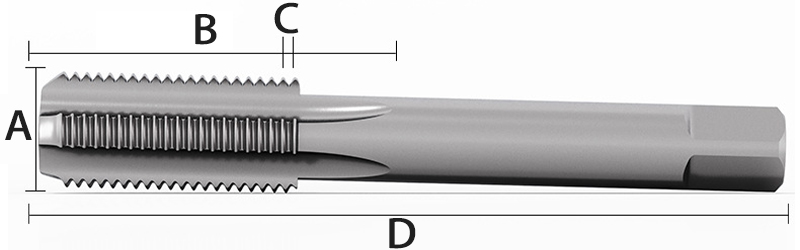

| Model | Diameter (A) | Working depth(B) | Tooth distance(C) | Total length(D) |

| M3 | 3 mm | 18.0 mm | 0.50 mm | 50.9 mm |

| M4 | 4 mm | 22.2 mm | 0.70 mm | 57.3 mm |

| M5 | 5 mm | 23.5 mm | 0.80 mm | 64.2 mm |

| M6 | 6 mm | 28.2 mm | 1.00 mm | 67.4 mm |

| M8 | 8 mm | 30.7 mm | 1.25 mm | 70.2 mm |

| M10 | 10 mm | 33.5 mm | 1.50 mm | 75.3 mm |

| M12 | 12 mm | 37.0 mm | 1.75 mm | 82.4 mm |

| M14 | 14 mm | 44.5 mm | 2.00 mm | 86.5 mm |

| M16 | 16 mm | 46.0 mm | 2.00 mm | 95.5 mm |

6542 high speed steel is preferred. High-quality high-speed steel with good toughness, strong wear resistance and excellent cutting performance.

Wide application, high cost performance and practicality.

Sharp without burrs. The thread of the tap is clear, the bite is precise, and the use is more convenient. Straight groove, spiral groove dual options.

Precautions

- According to different situations and usage scenarios, choose matching taps.

Straight flute taps are suitable for through holes and shallow blind holes for downward chip removal;

Spiral taps are suitable for upward chip removal in blind holes. - Choose the correct drill diameter. If the bottom hole is too small, the part that needs to be cut by the tap will increase, which will increase the risk of the tap breaking.

- The tapping material is impure, and there are local hard points or pores, which will cause the tap to lose balance and break instantly.

- At the beginning of tapping, the starting position of the tap needs to be accurate, that is, the axis of the spindle and the centerline of the bottom hole need to be on the same straight line.

- The tapping machine needs to meet the precision requirements of the tap. Using a high-precision tapping machine can better exert the performance of the tap.

- This product is a machine tap. Since the machine tap has high requirements on concentricity, manual tapping is prohibited.

There are no reviews yet.