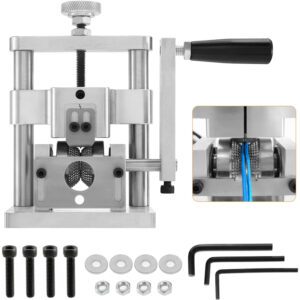

Adjustable Length Multi Core Cable Stripping Machine with Twisting

The Adjustable Length Multi Core Cable Stripping Machine with Twisting is a high-efficiency industrial solution designed for multi-core sheathed cable processing, including precise length cutting, inner core stripping, and conductor twisting. It is ideal for wire harness manufacturing and cable assembly applications that demand accuracy, consistency, and productivity.This machine with twisting features flexible length adjustment, allowing quick setup for different cable lengths and mixed long-short wire processing requirements.

$9.10

CompareTechnical Specifications:Wire Stripping Machine

| Weight (kg) | 35 |

| Copper wire stripping | 5-15 millimeters |

| Applicable wire area | 0.5-3.0 square meters |

| Dimensions (length * width * height) | 900 * 500 * 1360 meters |

| Pressure | 5-7 kilograms |

| Shorten the length | 20-290 millimeters |

Product Introduction

The Adjustable Length Multi Core Cable Stripping Machine with Twisting is a high-efficiency industrial solution designed for multi-core sheathed cable processing, including precise length cutting, inner core stripping, and conductor twisting. It is ideal for wire harness manufacturing and cable assembly applications that demand accuracy, consistency, and productivity.This machine with twisting features flexible length adjustment, allowing quick setup for different cable lengths and mixed long-short wire processing requirements. Its integrated stripping and twisting mechanism ensures clean insulation removal and uniform twisting of copper conductors, improving terminal quality and connection reliability.Built with a stable structure and user-friendly operation, the machine supports continuous and batch production. A high-precision control system guarantees consistent stripping length, twisting direction, and processing quality across all cables. Widely used in electrical control systems, industrial equipment, power harnesses, and automation manufacturing, this machine with twisting significantly enhances cable processing efficiency and overall product quality.

Application Scenarios