Powder and granule filling equipment automatically fill, measure, and seal powders or granulated products into bags, pouches, or containers. They ensure accurate dosage and consistent fill levels. These machines suit food, chemical, pharmaceutical, and industrial material packaging lines. Powder & granule fillers improve packaging speed and reduce manual labor. Reliable filling equipment maintains product quality and packaging efficiency.

Powder & Granule Filling Equipment

Showing 1–24 of 56 results

-

Powder & Granule Filling Equipment

0-70pcs/min Soap Cartoning Machine – Automatic Packaging

The automatic soap boxing machine is a high-efficiency packaging device specially designed for soap and similar block products. With precise automated control and flexible customization capabilities, it is widely used in the daily chemical industry and is also suitable for boxing needs in sectors such as food, beverages, and textiles. The equipment uses an advanced PLC control system, offering stable and reliable operation, capable of fully automated boxing processes. It ensures seamless coordination from product conveying, arranging, and boxing to sealing, significantly reducing manual intervention, lowering labor costs, and improving packaging consistency.

SKU: n/a -

Powder & Granule Filling Equipment

0.75kw Fully Automatic Three-Side Sealing Packaging Machine

The advantage of the fully automatic three-side sealing packaging machine lies in the deep integration of fully automatic operation and three-side sealing technology. The entire process requires no manual intervention—from powder feeding, precise measurement, pouch forming, three-side sealing to finished product output—achieving full-process automation, significantly improving packaging efficiency. Its core selling point, ‘high productivity,’ meets the needs of large-scale production and significantly reduces labor costs per unit. The three-side sealing design provides excellent sealing performance, completely isolating air, moisture, and contaminants, effectively preventing powder from caking or oxidizing, extending the food’s shelf life, and addressing the sealing challenges in powder packaging.

SKU: n/a -

Powder & Granule Filling Equipment

0.7kw Vertical Semi-Automatic Strapping Machine

The vertical semi-automatic strapping machine is specifically designed for plastic packaging materials and is compatible with various commonly used plastic straps. These materials are widely available and relatively inexpensive, effectively helping businesses control packaging supply costs. The core components include high-performance parts such as PLCs, engines, and bearings. The PLC system ensures precise control of strapping parameters, the engine provides stable power to guarantee equipment operation, and the bearings reduce component friction, enhancing operational smoothness and extending the machine’s lifespan. A major advantage of the equipment is its ease of use. It features a user-friendly control panel with intuitive parameter settings, allowing operators to start using the machine with minimal training, without requiring specialized skills, significantly reducing labor training costs.

SKU: n/a -

Powder & Granule Filling Equipment

0.8kw Multi-head weighing and filling machine for powder

The multi-head weighing filling machine integrates multiple practical functions such as stuffing, packaging, labeling, coating, sealing, punching, and counting, achieving one-stop operation for powder packaging and reducing the cumbersome process of coordinating multiple devices. The multi-head weighing design provides higher weighing accuracy, allowing precise control of powder filling amounts, preventing material waste and packaging specification errors. The machine’s structural layout is reasonable and easy to operate, with parameter settings and operation monitoring completed via the control panel. Whether it is flour and seasoning powder packaging in the food industry, laundry powder and cosmetic powder packaging in the daily necessities industry, or powder raw material packaging in the chemical industry, this multi-head weighing filling machine can efficiently, accurately, and multifunctionally complete the packaging of powders.

SKU: n/a -

Powder & Granule Filling Equipment

1.05kw Ultra-Light Clay Packaging Machine

The ultralight clay packaging machine emphasizes product protection and ease of operation. It adopts a gentle product handling approach, using soft-feel conveyors and custom molds to properly preserve the shape and texture of the clay during the packaging process, preventing deformation or damage caused by mechanical contact. The user-friendly operation design is reflected in the touchscreen HMI interface, allowing operators to easily set and adjust packaging parameters (length, speed, temperature) without the need for complex training. The durable construction is another major advantage of the equipment, with the body made of food-grade stainless steel and high-strength alloys, ensuring reliable long-term operation while meeting hygiene standards.

SKU: n/a -

Powder & Granule Filling Equipment

1.2kw Automatic Snack Packing Machine For Coffee Beans

In terms of packaging types, the automatic snack packaging machine has excellent equipment compatibility and can handle a wide range of packaging forms, including cartons, cans, bottles, drums, stand-up pouches, bags, films, metal foils, belt decorations, pouches, and cases. Whether it is puffed snacks like chips and nuts, or casual foods like jerky and candied fruits, as well as daily necessities and small hardware items that require special packaging, the machine can easily manage them. By flexibly switching packaging types and parameter settings, it can quickly respond to the market demands of different snack products and reduce equipment replacement costs.

SKU: n/a -

Powder & Granule Filling Equipment

1.2kw Gummy Candy Packaging Machine with Counting Function

The countable gummy packaging machine relies on a PLC intelligent control system and high-precision sensors for its core counting function. It can accurately recognize and count gummies of different shapes and sizes with minimal counting errors. The quantity of gummies per package can be set according to production needs, ranging from small trial packs with a few pieces to standard packages with dozens of pieces, ensuring precise control and effectively avoiding errors and inefficiencies associated with manual counting. Functionally, the machine also integrates multiple practical operations such as packaging, sealing, labeling, embossing, and capping. From counting and feeding gummies to packaging, forming, and labeling, it achieves full-process automation, significantly improving production efficiency.

SKU: n/a -

Powder & Granule Filling Equipment

1.2kw Non-stick Material Packaging Machine for Nut Powder

The non-sticky material packaging machine is a multifunctional packaging device specially designed for powders, granular, and other non-sticky materials. It operates pneumatically and is widely used in industries such as food, beverages, daily necessities, chemicals, machinery & hardware, cigarettes, and tobacco due to its long-lasting durability. The equipment is structurally optimized to suit the characteristics of non-sticky materials, enabling efficient operations from material filling to finished packaging. It provides enterprises with stable and reliable packaging solutions, particularly suitable for production settings with high requirements for the durability of packaging equipment.

SKU: n/a -

Powder & Granule Filling Equipment

1.35kw Automatic Powder Packaging Machine for Cornmeal Bags

The automatic powder packaging machine for corn flour bags is a high-efficiency packaging device specifically designed for powdered materials like corn flour. With precise measuring performance and intelligent configuration, it has become an ideal choice for corn flour packaging in the food processing industry. The equipment is optimized for the fine and easily airborne characteristics of corn flour, allowing seamless operations from material conveying to finished product sealing. It accommodates a measurement range of 1-100 grams, meeting the packaging needs of small sample packs, household packs, and other specifications, offering great flexibility.

SKU: n/a -

Powder & Granule Filling Equipment

1.4kw Toy Blind Box Packaging Machine

In terms of functionality, the toy blind box packaging machine integrates multiple core functions such as embossing, filling, labeling, sealing, packaging, laminating, capping, coating, boxing, gluing, and slitting. It also features automation capabilities including automatic coding, weighing, and feeding. From packaging formation to information labeling and weight inspection, it enables efficient operation throughout the entire process, significantly improving packaging efficiency and product quality stability.

SKU: n/a -

Powder & Granule Filling Equipment

1.5kw Horizontal Flow Packaging Machine for Dried Mango

The horizontal flow packaging machine is equipped with an adjustable bag former, which can be freely adjusted within a certain range. By simply providing the minimum and maximum sizes of the dried mangoes, the machine can be matched to the suitable model without frequent equipment changes, thereby reducing production costs. The blades support customized options, including single blade, double blade, rotary blade, and reciprocating blade. For packaging dried mangoes that are relatively large or over 10 cm in height, it is recommended to use a reciprocating blade. This ensures that the cut packaging bags are neatly and beautifully shaped with even seals. Although the cost is slightly higher, it can significantly enhance the packaging quality of the product, and it is usually used in conjunction with a servo-driven horizontal packaging machine.

SKU: n/a -

Powder & Granule Filling Equipment

1.5kw LEGO Brick Packaging Machine Multi-Function

In terms of practical design, the LEGO brick packing machine is equipped with a large carton storage capacity, allowing more empty cartons to be stored at once, reducing the frequency of carton replenishment by staff, significantly easing labor intensity, and enhancing the overall continuity of the production process. The overall structural design is reasonable, operating smoothly and efficiently, and can accommodate the packing needs of LEGO brick products of different specifications. Whether it’s small sets or large brick gift boxes, it can accurately complete the packing tasks. Whether for batch production in small and medium-sized toy companies or assembly line operations in large factories, this LEGO brick packing machine provides a professional solution for LEGO brick packaging with intelligent, efficient, and reliable performance.

SKU: n/a -

Powder & Granule Filling Equipment

1.5kw Toy Granule Soft Bag Packaging Machine

Although the toy granule soft bag packaging machine is primarily designed for packaging toy granules, it also boasts broad adaptability and can be extended to package granular materials in fields such as food, chemicals, machinery, and hardware. This meets the production needs of multiple industries and enhances the overall utilization of the equipment. High precision is its standout feature, capable of accurately controlling packaging measurement and sealing positions, ensuring each bag of toy granules is uniform in weight, neatly shaped, and aesthetically pleasing, thereby improving the overall product quality. At the same time, it adopts an energy-saving design, effectively reducing energy consumption while ensuring efficient operation, in line with the enterprise’s green production concept and reducing production costs.

SKU: n/a -

Powder & Granule Filling Equipment

10-25bags/min Granule Film Packaging Machine

The granule film packaging all-in-one machine features intelligent operation with a user-friendly touchscreen, allowing operators to easily adjust packaging parameters such as package weight, bag length, and sealing temperature. It also supports storing multiple sets of parameters, so when switching between different product specifications, there is no need to reset the machine; preset parameters can be directly called, significantly reducing changeover time and improving work efficiency. The equipment integrates material storage and finished product packaging into a single operation, greatly simplifying the production process and enhancing overall production efficiency. It is especially suitable for large-scale packaging of various granular materials such as grains, feed, chemical pellets, and pharmaceutical granules.

SKU: n/a -

Powder & Granule Filling Equipment

100pcs/min Powder Packaging Machine – Vacuum Feeding

The dust-collecting feeding system of the powder packaging machine is a supporting device designed to solve problems such as dust pollution, material waste, and cumbersome manual operation during the powder material conveying process. This system adopts the principle of negative pressure suction, accurately connecting the storage bin to the packaging machine’s feeding port through a sealed pipeline. Combined with a high-performance vortex air pump to generate a stable negative pressure, it enables automated, contactless transportation of powder materials, completely preventing dust spillage from the source and ensuring a clean production environment and the health of operators.

SKU: n/a -

Powder & Granule Filling Equipment

20 bags/min Nut and Bolt Packaging Machine – Counting

The core configuration of the nut and bolt packaging machine highlights intelligence and precision, equipped with a PLC control system and a 7-inch touch screen. It is easy to operate and supports multiple languages, allowing operators to quickly complete parameter settings and mode switching through an intuitive interface, easily adapting to both domestic and overseas production environments. It is equipped with a Fiber Counting System and a Vibrating Bowl with a high-accuracy fiber counting device . The vibrating bowl ensures orderly feeding of parts, while the high-precision counting device guarantees accurate quantity in each bag, preventing product quality issues and cost control problems caused by counting errors.

SKU: n/a -

Powder & Granule Filling Equipment

20bags/min Automatic Weighing Seed Packaging Machine

The automatic weighing sunflower seed packaging machine significantly reduces reliance on manual labor through automation. From sunflower seed feeding, intelligent weighing, quantitative filling to sealing, the entire process requires no manual intervention. A single operator can handle equipment operation and maintenance, greatly improving packaging efficiency and reducing labor costs. The packaging types support various specifications such as bags, films, foil, and pouches, allowing flexible switching according to sales needs and enabling the production of small-pack independent packaging. It is suitable for multiple industries, including food, beverage, and daily necessities. This equipment has a compact structure and occupies minimal space, making it suitable for various factory layouts. The user interface is intuitive and easy to understand, allowing workers to operate it after simple training. Core components are made of wear-resistant and corrosion-resistant materials, easy to clean and maintain, and comply with food industry hygiene standards.

SKU: n/a -

Powder & Granule Filling Equipment

20bags/Min Automatic Tea Bag Packaging Machine For Coffee Powder

In terms of power and control technology, the automatic tea bag packaging machine is equipped with a servo drive system, achieving high-precision positioning control with minimal packaging size errors, ensuring uniform specifications for each tea bag. The pneumatic-electric separation structure independently arranges the pneumatic and electrical controls, greatly enhancing operational stability while reducing equipment noise and creating a more comfortable production environment. The machine’s dual-servo film-pulling technology ensures even tension of the packaging film, resulting in neatly formed tea bags and effectively preventing material loss caused by film misalignment or damage.

SKU: n/a -

Powder & Granule Filling Equipment

20pcs/min Spice Sachet Packaging Machine – Fully Automatic

The spice sachet packaging machine is a fully automatic electric packaging device designed specifically for small-dose materials. It is especially suited for the packaging needs of food, spices, powders, and granular products, providing efficient and convenient packaging solutions for small and medium-sized enterprises and mass production scenarios. Focusing on the precision of small-dose packaging, the machine’s packaging range is set from 1-200 grams, perfectly covering the single-pack specifications of common spices and seasonings. Whether it is fine powdered spices like pepper or chili powder, or materials like coffee beans and miscellaneous grains, it can achieve accurate packaging.

SKU: n/a -

Powder & Granule Filling Equipment

220kg High-Precision Powder Packaging Machine For Coffee Powder

The core components of the high-precision powder packaging machine are all selected from high-quality parts, including the motor, pressure vessel, pump, PLC, gears, engine, bearings, and more, to ensure the stability and longevity of the equipment from a hardware perspective, reducing maintenance and replacement costs in the future. The configuration also includes a temperature control meter and a counting sensor device. The temperature control meter ensures stable operating temperatures, while the counting sensor device can accurately track production output, facilitating production management. The high-precision packaging machine operates with low noise, creating a quiet production environment and minimizing the impact of noise pollution on workers. Its flexible manufacturing features allow it to be adjusted according to different specifications, making it suitable for various coffee powder packaging scenarios.

SKU: n/a -

Powder & Granule Filling Equipment

250kg Heat Sealing Automatic Packaging Machine for Corn Flour

The heat-sealing automatic packaging machine is designed for 220V 50/60Hz voltage and operates with a stable motor-driven mode, providing consistent power output that meets the demands of long-term continuous production. Its core heat-sealing function is equipped with an intelligent PID temperature controller, allowing precise adjustment of temperature settings. It is suitable for a variety of packaging materials such as plastics, paper, CPP, and OPP. Whether sealing laminated films or different types of paper, it can achieve tight and reliable heat seals, effectively preventing moisture and leakage, ensuring the safe storage and transportation of products. The packaging styles are flexible and diverse, supporting custom specifications for back-sealed bags, side-sealed packs, chain bags, perforated bags, and more, meeting different product packaging, display, and usage requirements.

SKU: n/a -

Powder & Granule Filling Equipment

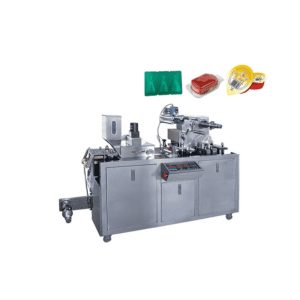

3.2kw Blister Packaging Machine For Flat Capsules Sealing

In terms of electrical control and functional adaptability, the blister packaging machine adopts an advanced control system, offering stable and reliable performance. It can be equipped with material shortage and leakage filling devices as well as material shortage detection and rejection devices according to the actual needs of customers, effectively reducing material waste and defective products, while improving production efficiency. The machine is designed in modular sections, integrating PVC forming, feeding, and heat sealing into one section, while hot aluminum cold forming, heat sealing, and punching are handled as another section for separate packaging. This modular structure not only makes operation and maintenance convenient but also allows flexible adaptation to different packaging materials and process requirements, enhancing the versatility of the equipment.

SKU: n/a -

Powder & Granule Filling Equipment

30 bags/min Coffee Capsule Filling Machine – High Productivity

The high-efficiency coffee capsule filling machine, in terms of power and specifications, uses pneumatic power and operates with a standard 220V voltage, ensuring stable operation and reasonable energy consumption, suitable for the power and air supply conditions of most factories. Functionally, it integrates multiple practical features, including filling with core ingredients, packaging, labeling, capping, coating, sealing, punching, gluing, and counting. It not only completes the core coffee capsule filling and packaging processes, but also simultaneously performs auxiliary operations such as label application and quantity counting, ensuring consistent packaging quality and accurate information for each batch of products.

SKU: n/a -

Powder & Granule Filling Equipment

30 bags/min Small Plastic Parts Packaging Machine

The small plastic parts packaging machine stands out for its convenience and is equipped with a PLC control system, allowing operators to easily complete parameter settings and switch packaging modes through an intuitive interface, reducing the operational threshold and training costs. Its core performance advantages are significant: seals are firm and tight, effectively preventing plastic parts from falling out or getting damp during storage and transportation; the bag shape is smooth and elegant, enhancing the neatness and professional appearance of the packaging; meanwhile, it combines high efficiency with durability, reliably handling small to medium batch packaging tasks, and comprehensively enhancing the continuity and intelligence of the packaging process.

SKU: n/a