Cutting Fluids & Coolant Systems

Waterborne Concrete Release Agent Cement Construction Plastic Mold Release Agent Detergent

- Long anti-rust period

- Efficient and durable demoulding

- Low freezing point, fast drying

- Effectively protect the mold

- Good cleaning effect

$111.00 – $984.00

CompareProduct parameters of the Waterborne Concrete Release Agent

| Product Type | Water-Based Mold Release Agent |

| Product Appearance Liquid | Reddish-brown oily liquid |

| PH value of stock solution | 8.5~10.0 |

| Diluent anti-rust test (55 ± 28 ° C) | Steel sheet ≥ 24h |

| Dilution corrosion test (35±2°C) | Steel sheet≥24h |

| Drying time | 15-30min |

| Use ratio | 1:5-7 |

| Applicable mold | Steel mold/wooden mold/plastic mold |

Product advantages of the Waterborne Concrete Release Agent

- Long anti-rust period

During the demoulding process, metal molds are prone to rust when in contact with water, and the release agent has a certain anti-rust performance, thereby reducing the rust of metal molds and reducing production costs. - Efficient and durable demoulding

It is made of special mold release additives, surfactants, preservatives, brighteners, etc., which are formulated by special technology. It is diluted with water and emulsified. It has good mold release effect and good surface brightness. - Low freezing point, fast drying

The polymer composition of the release agent can ensure the normal use in low temperature environment, and accelerate the drying degree of the material, and quickly form an isolation film to improve the release efficiency. - Effectively protect the mold

Adsorb various particles and form a layer of adsorption film to lubricate and isolate the inner wall of the formwork. Make the concrete and the formwork separate smoothly when removing the formwork, keep the integrity of the concrete shape and the cleanliness of the mold. - Good cleaning effect

The release agent diluent has a good cleaning effect and can remove oil and dust. It can be used as a mold cleaning agent to simplify the concrete forming process.

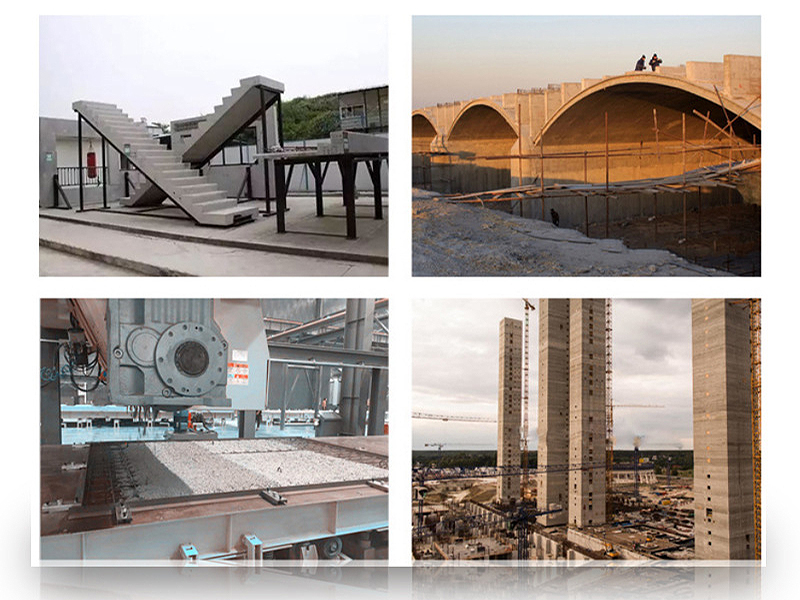

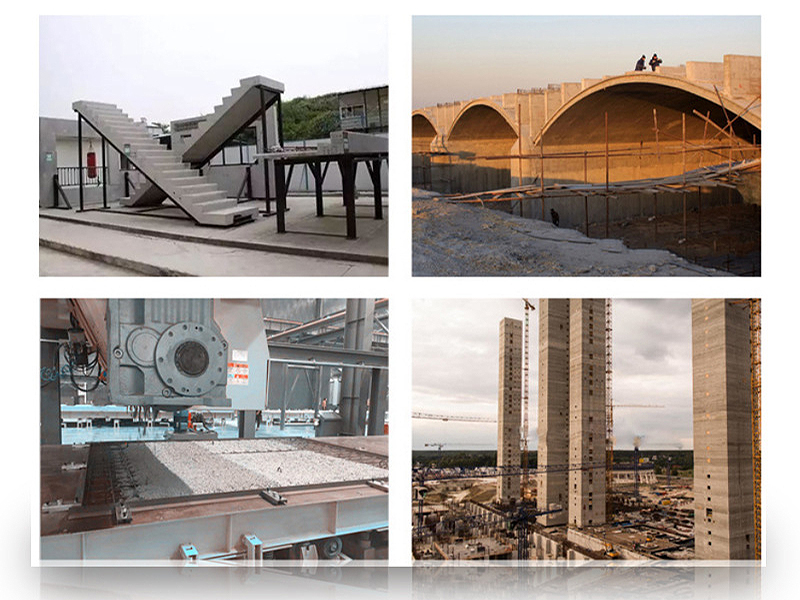

Application Scenario

| Volume | 18KG, 180KG |

|---|

There are no reviews yet.