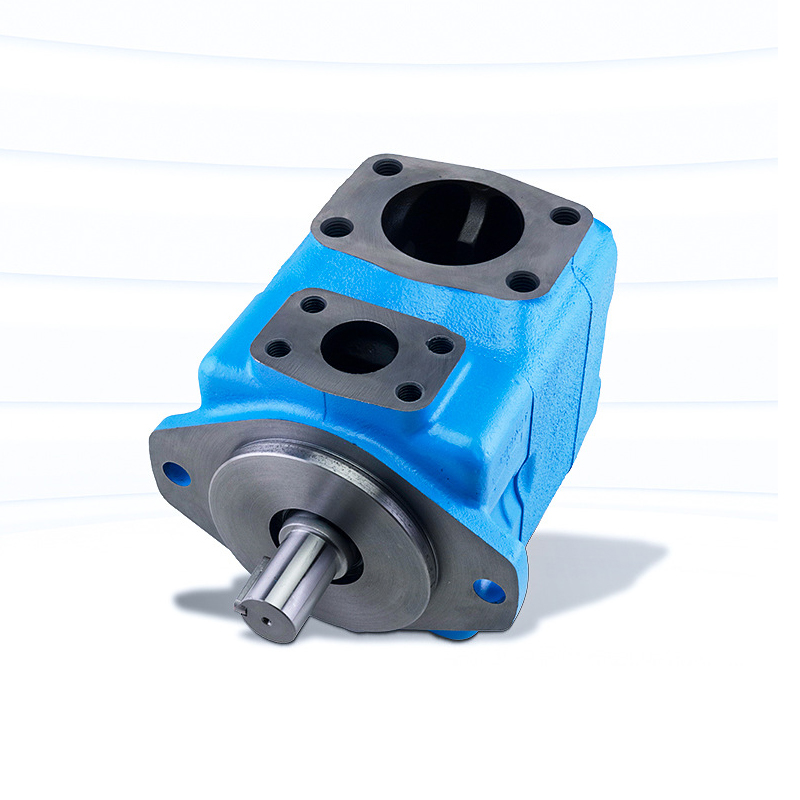

Vane pump 45V-60A-1C-22R machine tool engineering machinery high pressure master hydraulic vane pump

pump start

1. Before starting the oil pump, check the inlet and steering, and do not make mistakes in the direction.

2. Fill the pump with oil for the first start, and turn the coupling by hand. The rotation force should feel even and flexible.

3. When the machine is started for the first time or after a long-term shutdown, it will cause air suction. Therefore, an exhaust valve should be installed at the output port, or the outlet flange should be slightly loosened to remove air, and a test run should be carried out under no-load conditions as much as possible.

$595.00

CompareVane pump Precautions for installation

1. The installation location is optional. During trial operation, the pump body must be filled with hydraulic fluid and kept full during operation. To reduce noise, all connecting piping (inlet, pressure and case drain) is isolated from the tank by flexible elements.

2. The support seat of the oil pump should be firm, have good rigidity, and can fully absorb vibration.

3. The concentricity of the pump and motor shafts is controlled within 0.100mm, and flexible couplings are used as much as possible to avoid bending moments and axial loads on the pump bearings.

4. The diameter of the suction pipe of the oil pump should not be smaller than the diameter of the pump inlet, and the flow rate of the oil suction filter should not be less than twice the flow rate of the oil pump. The finer the oil filter, the better the cleanliness of the working fluid, and the longer the life of the oil pump.

5. When the pump is installed higher than the oil tank, the height from the suction port to the oil level should be less than 1 meter (less than 0.8 meters when using phosphate ester or water-containing hydraulic fluid)

6. When the pump is installed, if it is higher than the liquid level of the oil tank, the suction center of the pump should be upward.

7. Note that the flanges, joints, and the entire oil suction pipeline at the oil inlet must be strictly sealed to prevent air leakage, otherwise it will cause noise, system vibration, and generate a lot of foam in the oil tank, reducing the service life of the pump.

8. The oil tank should be equipped with a partition to separate the air bubbles and dirt brought by the oil return. The oil return pipe should extend below the oil surface (it must not be directly connected to the inlet of the pump) to prevent air bubbles from being splashed by the return oil.

There are no reviews yet.