Juice making machine/industrial cold press juicer|commercial cold press juicer

installation and use

1. Secure the four corners of the machine

2. Fill the oil tank with clean hydraulic oil, and the oil level of the oil tank should reach the upper limit of the cursor (it has been filled up before leaving the factory, please check it again before testing the machine, note: use N46 special anti-wear hydraulic oil)

3. Connect the power supply, check whether the grounding of the electrical equipment is reliable, and then send power for a short time, and observe the rotation direction (counterclockwise) from the fan end of the motor. If it is inconsistent, you can change the wire connector. Then start the motor, first control the oil cylinder to move up and down several times without load, and then load and work after it is normal.

4. The hydraulic oil needs to be replaced once a year.

5. If the hydraulic oil is found to be emulsified, cloudy or sticky, the hydraulic oil should be replaced immediately. 6. Please read the instruction manual carefully before using the machine, and correctly grasp the operation method for safe production. If you still have doubts after reading the instruction manual or feel difficult to deal with the fault, please contact our company, and our professional technicians will serve you enthusiastically.

$3,750.00

Compare| Juice making machine/industrial cold press juicer|commercial cold press juicer | |||

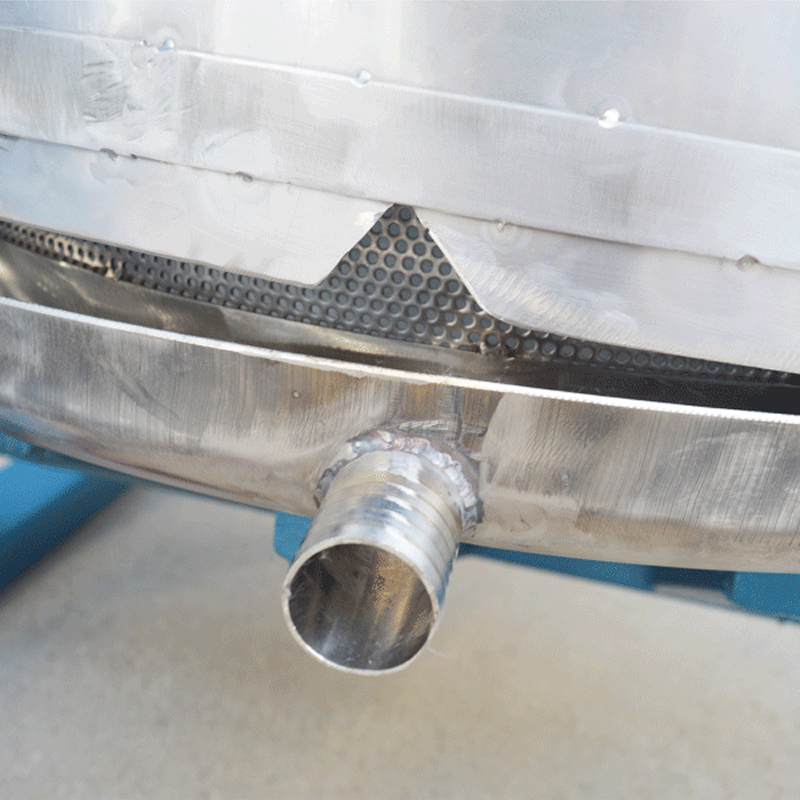

| Name | Hydraulic press machine | Material | Cast Iron & 304 SUS |

| Capacity | 160L | PN | 1000KZ |

| Size | 80*115*200cm | PB | 16mpa |

| Oil Pump Motor Power | 1.5kw | Electromagnetic Valve Votage | 220V |

| Oil Pump Motor Votage | 3 phases 380V | Diameter of Hole | 3mm |

| Thickness | 1mm & 2mm & 6mm | Net Weight | 230kg |

| Feeding Way | Use the included trolley to feed the row material | ||

| Instruction | 1. Stabilize the four corners of the machine. 2. Add the fuel tank to the clean hydraulic oil. The position of the oil level of the fuel tank should be added to the upper limit of the cursor. (The factory has been filled up. Please check again before testing the machine. Note: Use N46 special anti-wear hydraulic oil) 3. Connect the power supply, check whether the grounding of the electrical equipment is reliable, and then send the power for a short time. Observe the direction of rotation (counterclockwise direction) from the fan end of the motor. If it is inconsistent, replace the wire connector. Then start the motor, first move the control cylinder up and down several times, and then load the work after normal. 4. Hydraulic oil needs to be replaced once a year. 5. If the hydraulic oil is found to be emulsified, turbid or viscous, the hydraulic oil should be replaced immediately. 6. Please read the instruction manual carefully before using the machine, and correctly master the operation mode for safe production. If you are still confused after reading the instruction manual or have difficulty in handling the problem, please contact us and our professional technicians will serve you enthusiastically. |

||

| Warning | During operation of the machine, it is strictly forbidden to enter any space below the machine beam by any part of body. | ||

There are no reviews yet.