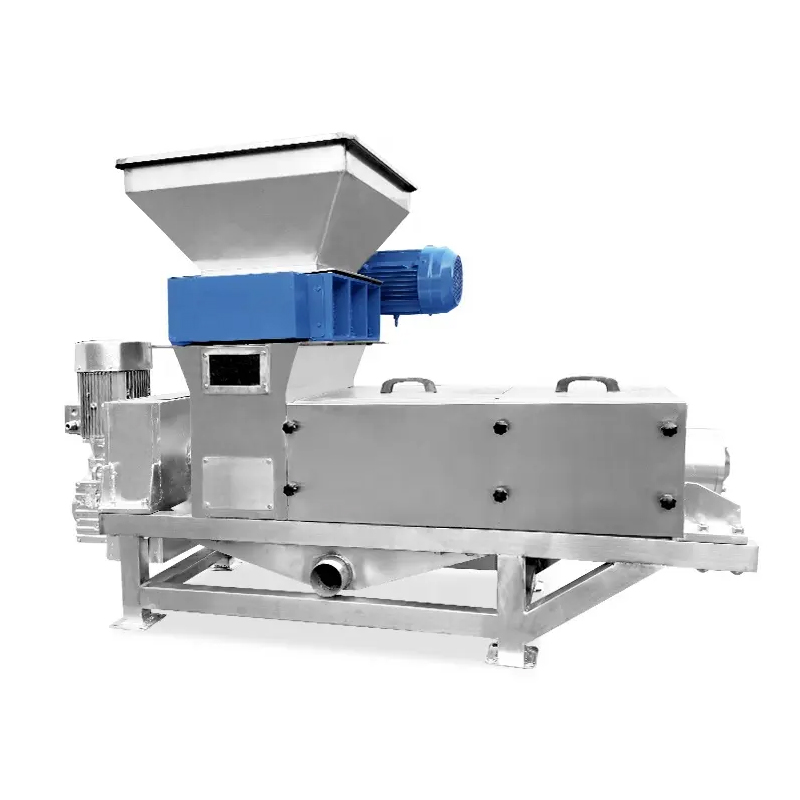

Multi-functional Industrial Coconut milk Juice Machine/Juicer Hydraulic Press/Vegetable Passion Fruit Juicer Extractor Machine

1>Plungertype pump provide oil to hydraulic system pressure and control the pressure through the adjustable pressure relief valve,Two fuel tanks mounted on the rea bearing seat,to control the size of the material outlet and the moisture of the slag through piston rod extending.

2>The installation direction of extracting screw and conveyor screw of double extractor is in opposite direction.

3>The outlet is conical body and controlled by the hydraulic cylinder or spring, to adjust the hydraulic or spring to adjust the strength. The material contacting part are made of stainless steel.

$4,620.00

CompareIntroduction of sugar beet press machine

1>Plungertype pump provide oil to hydraulic system pressure and control the pressure through the adjustable pressure relief valve,Two fuel tanks mounted on the rea bearing seat,to control the size of the material outlet and the moisture of the slag through piston rod extending.

2>The installation direction of extracting screw and conveyor screw of double extractor is in opposite direction.

3>The outlet is conical body and controlled by the hydraulic cylinder or spring, to adjust the hydraulic or spring to adjust the strength. The material contacting part are made of stainless steel.

Technical parameters of sugar beet press machine

|

Model |

FR-180 |

FR-260 |

FR-350 |

FR-420 |

FR-500 |

FR-600 |

|

Capacity(T/H) |

0.2-0.5T |

1T-1.5T |

1.5T-3T |

3T-5T |

6T-10T |

10t-15t |

|

Power |

3kw |

5.5kw |

7.5kw |

11kw |

18.5KW |

22KW |

|

Diameter of screw |

180mm |

260mm |

350mm |

420mm |

500mm |

600mm |

|

Speed |

12r/min |

12r/min |

12r/min |

12r/min |

12r/min |

12r/min |

|

Adjustment method |

Spring adjustment |

Spring adjustment |

Spring adjustment |

Hydraulic adjustment |

Hydraulic adjustment |

Hydraulic adjustment |

|

Mesh size (mm) |

1mm (adjustable) |

1mm (adjustable) |

1mm (adjustable) |

1mm (adjustable) |

1mm (adjustable) |

1mm (adjustable) |

|

Material |

304 stainless steel for the suspension contacts part, add fee can customized to be whole stainless steel |

|||||

|

Voltage |

380V/220V |

380V/220V |

380V/220V |

380V/220V |

380V/220V |

380V/220V |

|

Weight |

550kg |

900kg |

1300kg |

26000kg |

3050kg |

4300kg |

|

Dimension(cm) |

170*50*80 |

220*60*90 |

350*70*100 |

358*100*147 |

374*120*165 |

450*130*165 |

Features of sugar beet press machine

1>all kinds of bran, sea buckthorn fruit, ginger (to be broken), bamboo shoots and other fruit and vegetable juice;

2>lees after fermentation of rice bran, sawdust, wood fiber, bagasse, tea slag dewatering; through anaerobic fermentation of cassava residue after dehydration; Gynostemma, Ula grass, celery, the dregs (non smooth), etc. dehydration; Sweet sorghum, wheat straw, rice straw, reeds, etc. dehydration;

3>garbage and other environmental industries dewatering.

4>The pressure can be adjusted easily.

There are no reviews yet.