Shrink Wrapping

Heat Shrink Wrapping Machine 2000-2500 PCS/H Adjustable Speed Plastic Film Sealing Machine Product Packaging Machine

This machine is widely used in the appearance packaging of food, electronics, toys, hardware tools, cosmetics, medicines, daily necessities, books, electrical appliances, bamboo and wood utensils and other products.

After packaging, it has the functions of beautiful appearance, dustproof, moistureproof and damageproof. Improved product image and low packaging costs.

Maximum packaging size: W450mm×H250mm

Work efficiency: 2000-2500/H

$1,695.00

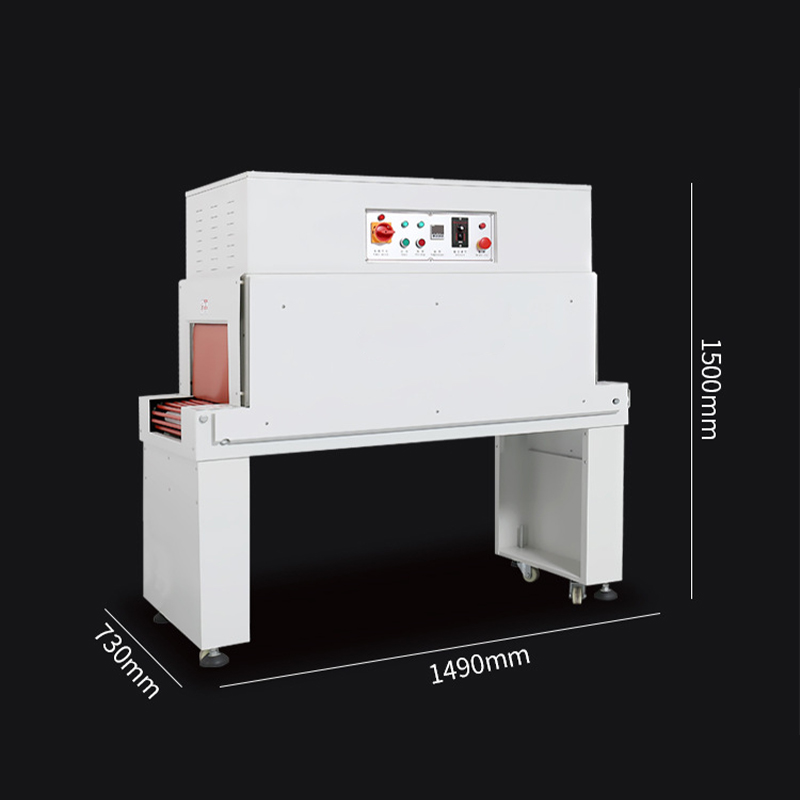

CompareBasic parameters of the Heat Shrink Wrapping Machine

| Maximum packaging size | W450mm×H250mm |

| Power supply | 3/380V50/60Hz |

| Work efficiency | 2000-2500/H |

| Power | 9KW |

| Net weight | 180Kg |

| Mechanical dimensions | L1500mm×W730mm×H1500mm |

Product advantages

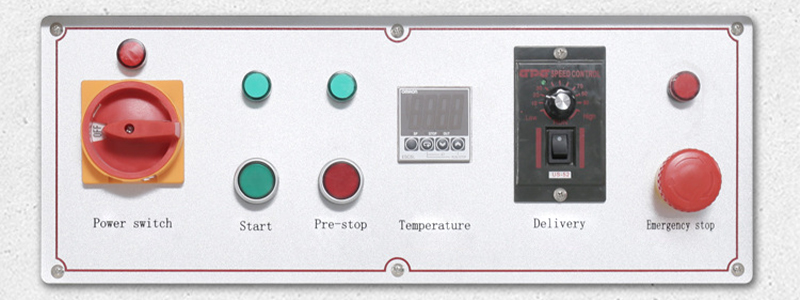

- Switches, thermostats and other main electrical parts are all made of famous factory components, which work stably and have a low failure rate.

- Combined with the advanced shrinkage air delivery technology, and the unique design and manufacture after improvement, the air delivery is uniform and the shrinkage effect is good.

- Use high-temperature cloth to prevent heat dissipation and ensure minimal heat loss.

- The conveying and air transporting motors use components from famous manufacturers, are powerful and can work continuously for a long time.

- Using stainless steel heating tube, it has long service life and high energy efficiency. The conveyor adopts a new type of roller with a silicone cover on the outside, which is resistant to high temperatures, wear and tear, does not iron the film, does not deform, and can be used for a long time.

There are no reviews yet.