Good Quality Single Action Pneumatic Driven Oxygen Booster Pump

Application: Nitrogen filling stations ,charging high pressure gas cylinders and receivers.

Gas assisted plastic injection molding Hydraulic accumulator charging ,Components testing ,Automotive hoses and component gas testing ,biogas charging and pressure tank vessel leakage testing

$1,690.00

CompareApplication : Nitrogen filling stations ,charging high pressure gas cylinders and receivers.Gas assisted plastic injection molding Hydraulic accumulator charging ,Components testing ,Automotive hoses and component gas testing ,biogas charging and pressure tank vessel leakage testing

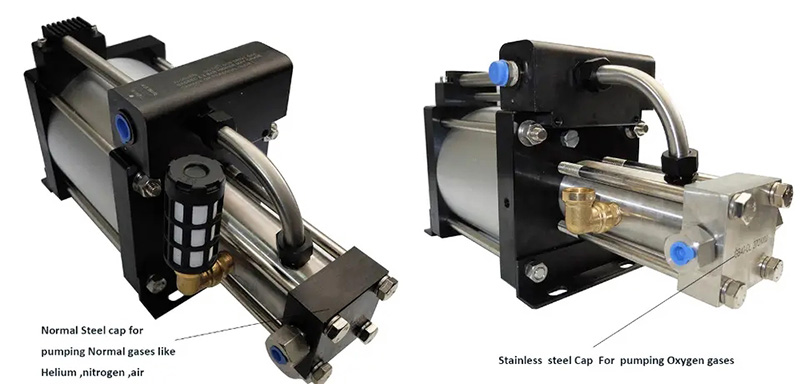

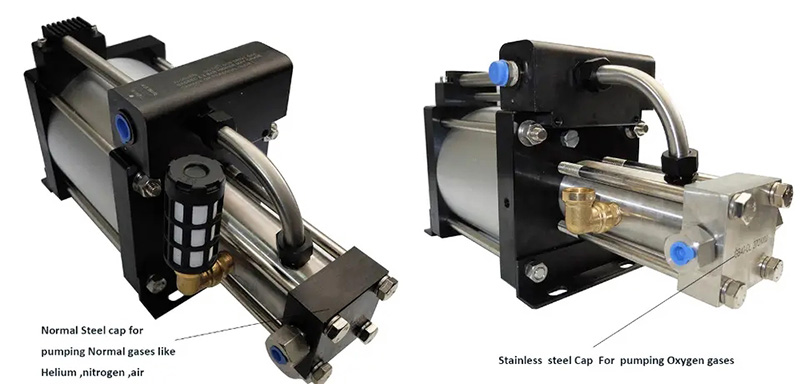

Booster Pump Product Configuration

Single Acting,single stage boosters are the smallest amd lightest with pressure up to Maximum 900 Bar .

Double acting,Single stage provides twice the delivery of a single acting ,single stage booster .

Two stage models are avaible for high gas compression ratios

| Item | Single action air Fuel oxygen Gas booster pump | |

| Action type | Single air driven,single action | |

| Dealing with air source | Dry and clean air filtered regulator with size port of G1/2” | |

| lubrication | Yes and Non-lubrication for oxygen gas | |

| Operating temperature | -4 to 65 degrees for air driven section and Maximum 115 degrees for high pressure gas barrel | |

| Theory of

operation |

The gas booster consist of a large reciprcating air driven piston directly and coupled by a connecting rod to small area gas piston.The gas piston operates in a high pressure gas barrel section and each gas barrel end contains high pressure inlet and outlet check valves | |

| Air pressure range | Compressed air 3-8 Bar | |

| Suitable gases for pump | Nitrogen,Helium,Breathing air ,Carbon dioxide ,Argon ,Neon and oxygen gas .

Noted : liquified gases ( Propane ,Co2 ,Halons) Can be boosted in a liquid and gas in controlled applications |

Product features:

1. Realiable ,Easy to Maintain ,compact and robust

2. No heat,flame or spark risk

3. Infinitely variable cycling speed and output

4. Air driven Models do not require electrical connection ,easy to apply automatic controls

5. No limit or adverse affect to contineous stop/start applications

6.Seals system designed for long working life,No airline lubricated required

7.Built-in coupling system (Most models) and suitable for most gases boosting

There are no reviews yet.