Fruit juice pressing machine/machine make fruit juice press/commercial hydraulic juice press machine

1. Usage: Our machine is used for removing the juice(water) from fruit and vegetable etc. by hydraulic pressing. It is mainly used for

fruit juice extracting, vegetable dehydration, medicine juice extracting etc.

2. Structure: hydraulic

The hydraulic cylinder adopts 4 sealing forms, greatly improving the service life of the oil cylinder, and simultaneously preventing the hydraulic oil from seeping out and polluting the food.

3. Features: Mechanical cold press,high juice yield rate, pure juice quality.

4. Widely use: It can press all kinds of fruits and vegetables to get the juice.

5. The pressure can be customized from 30tons to 500tons.

$3,750.00

Compare1. Usage: Our machine is used for removing the juice(water) from fruit and vegetable etc. by hydraulic pressing. It is mainly used for

fruit juice extracting, vegetable dehydration, medicine juice extracting etc.

2. Structure: hydraulic

The hydraulic cylinder adopts 4 sealing forms, greatly improving the service life of the oil cylinder, and simultaneously preventing the hydraulic oil from seeping out and polluting the food.

3. Features: Mechanical cold press,high juice yield rate, pure juice quality.

4. Widely use: It can press all kinds of fruits and vegetables to get the juice.

5. The pressure can be customized from 30tons to 500tons.

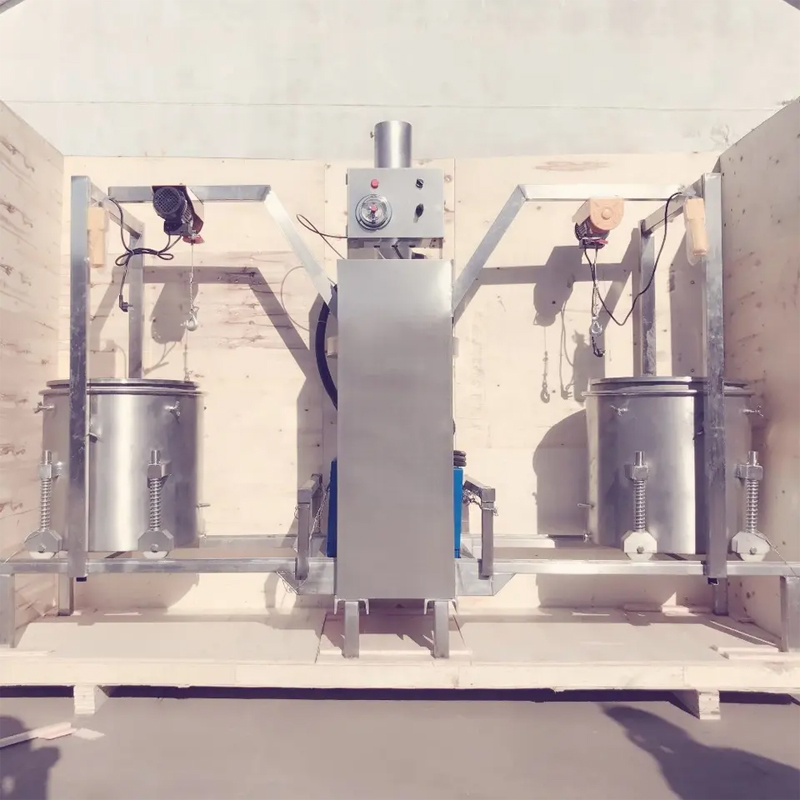

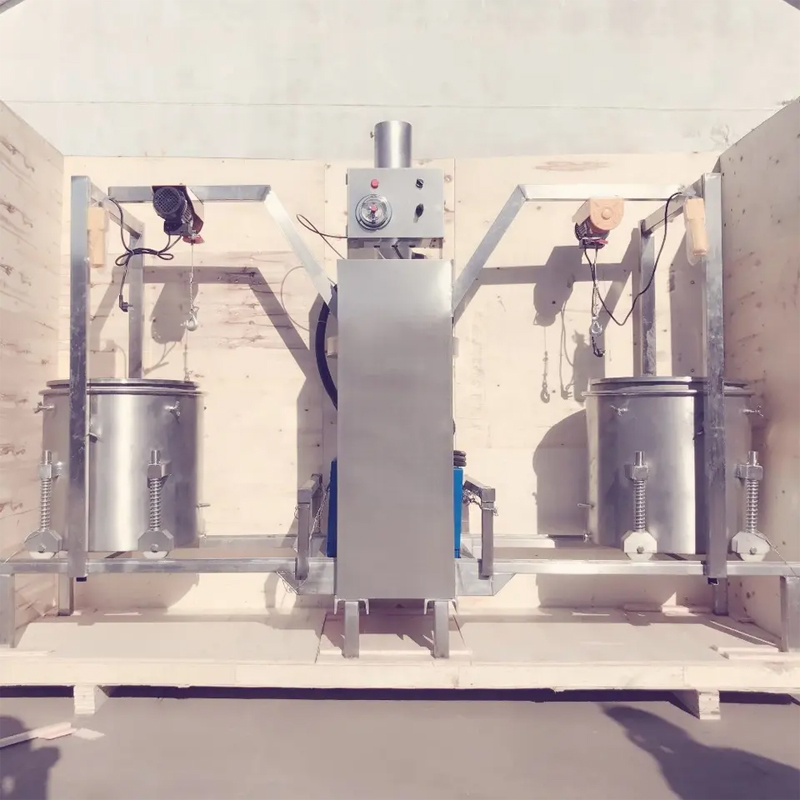

Hydraulic juicer press machine has single barrel type, double barrel type, automatic discharging type, bottom discharging type.

Users can choose Fruit juice pressing machine/machine make fruit juice press/commercial hydraulic juice press machine according to their different technical requirements.

The double barrel type can increase 2 times of capacity.. It is very good for dehydrating or juicing from all kind of bean

products, pickled vegetables, medicinal herbs, vegetables and so on.

The base of machine is made of special technology, ensure the stability and continuous of pressing , make sure the average of dewatering. The basket is produced by one time molding process, inner face was fine polished, easy for washing and cleaning, ensure the safety and hygiene of juice. The barrel and pressing plate are all made of high quality acid and alkali resistant 304 stainless steel.

Features of Fruit juice pressing machine/machine make fruit juice press/commercial hydraulic juice press machine

1. simple to use

2. durable using, easy maintenance

3. high pressing pressure

4. high capacity

|

Model

|

Size of barrel

|

Pressure

|

Size for semi-automatic

|

Size for Automatic

|

Power

|

Remarks

|

|

50L

|

φ400×500

|

30 tons

|

1200x642x1760

|

2.2kw

|

Single barrel

|

|

|

100L

|

φ500×500

|

30 tons

|

1300x736x1760

|

2.2 kw

|

Single barrel

|

|

|

100L

|

φ500×500

|

30 tons

|

2000X736X1760

|

2.2 kw

|

Double barrel

|

|

|

150L

|

φ550×600

|

30 tons

|

1800x786x2010

|

1600x880x2080

|

3 kw

|

Single barrel

|

|

150L

|

φ550×600

|

30 tons

|

3000x786x2010

|

2500x880x2080

|

3 kw

|

Double barrel

|

|

200L

|

φ600×700

|

50 tons

|

1850x886x2210

|

1730x940x2210

|

4 kw

|

Single barrel

|

|

200L

|

φ600×700

|

50 tons

|

3150x886x2210

|

2600x940x2210

|

4 kw

|

Double barrel

|

|

300L

|

φ700×750

|

50 tons

|

1900x942x2310

|

1800x1040x2310

|

4 kw

|

Single barrel

|

|

300L

|

φ700×750

|

50 tons

|

3250x942x2310

|

3000x1010x2310

|

4 kw

|

Double barrel

|

|

400L

|

φ800×800

|

50-500 tons

|

2000x1000x2410

|

2000x1140x2500

|

4-22kw

|

Single barrel

|

|

400L

|

φ800×800

|

50-500 tons

|

3400x1000x2410

|

3000x1140x2500

|

4-22kw

|

Double barrel

|

|

500L

|

φ850×900

|

50-500 tons

|

2200x1042x2620

|

2200x1140x2620

|

4-22kw

|

Single barrel

|

|

500L

|

φ850×900

|

50-500 tons

|

3600x1042x2620

|

3400x1140x2620

|

4-22kw

|

Double barrel

|

There are no reviews yet.