EF Hydraulic Filler Air Filter EF25-120 Hydraulic Station Fuel Tank Filler Port Air Filter High Quality durable Hydraulic Filters

NOTE: Prices may vary by product model and material.

- The hydraulic air filter is a new type of hydraulic accessory, and they have eight specifications. The structure of this product is composed of two parts: air filter and oil filter.

- The copper-based powder metallurgy sintered filter is used, which has the characteristics of stable filtration accuracy, high strength, strong plasticity, easy disassembly and cleaning, and can withstand thermal stress and impact and work normally under high temperature.

- The air filter can keep the oil in the oil tank clean, prevent dirt particles from entering the oil tank from the outside, and prolong the working cycle and service life of the oil and components.

$5.00 – $40.00

CompareWorking principle of the EF Hydraulic Filler Air Filter

When the hydraulic system is working, the oil level in the fuel tank rises or falls from time to time, the air is discharged from the inside to the outside when it rises, and the air is sucked in from the outside to the inside when it falls. In order to purify the fuel tank and the internal oil, an air filter is installed vertically on the fuel tank cover to filter the inhaled air. At the same time, the air filter is also an oil injection port, and the new working oil injected must be filtered before entering the oil tank, thereby filtering out the dirt particles in the oil.

In the hydraulic system, the purification of working oil is a very important link. The air filter can keep the oil in the oil tank clean, prevent dirt particles from entering the oil tank from the outside, and prolong the working cycle and service life of the oil and components, thus ensuring the normal operation of the hydraulic system. In addition, when the hydraulic system is working, the air filter can maintain the pressure in the oil tank and the atmospheric pressure to balance to avoid possible cavitation in the pump.

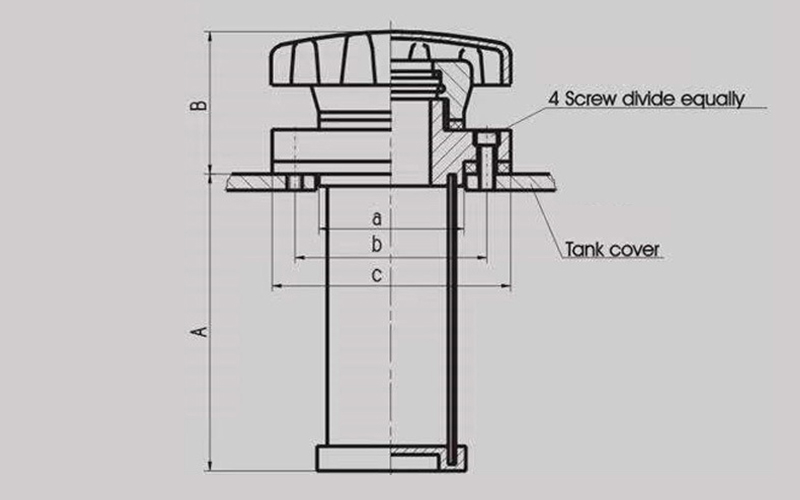

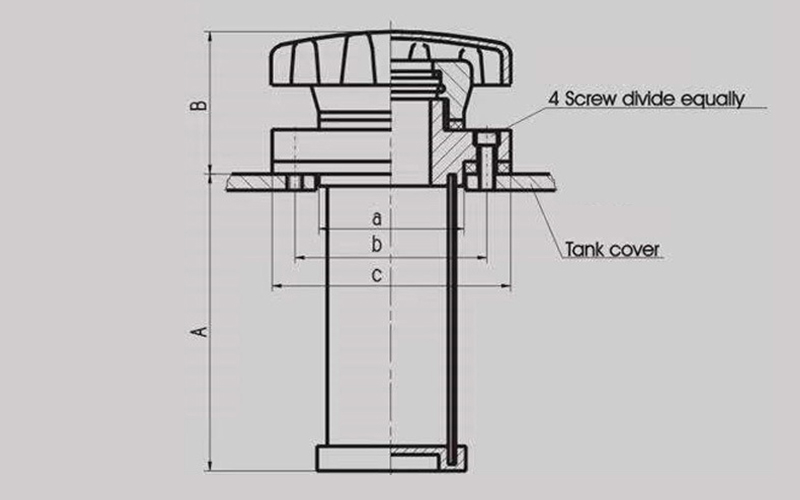

| Model | EF1-25 | EF2-32 | EF3-40 | EF4-50 | EF5-65 | EF6-80 | EF7-100 | EF8-120 |

| Filter flow(l/min) | 9 | 14 | 21 | 32 | 47 | 70 | 110 | 130 |

| Air flow rate(l/min) | 65 | 105 | 170 | 260 | 450 | 675 | 1055 | 1512 |

| Oil filter area(cm³) | 80 | 120 | 180 | 270 | 400 | 600 | 942 | 1370 |

| A | 80 | 100 | 120 | 150 | 190 | 220 | 274 | 333 |

| B | 45 | 50 | 55 | 59 | 70 | 80 | 88 | 98 |

| a | φ39 | φ47 | φ55 | φ66 | φ81 | φ96 | φ118 | φ138 |

| b | φ51 | φ59 | φ66.5 | φ82 | φ102 | φ120 | φ140 | φ160 |

| c | φ64 | φ70 | φ80 | φ98 | φ120 | φ140 | φ160 | φ180 |

| Screw(mm) | M4×10 | M4×10 | M5×14 | M6×14 | M8×16 | M8×16 | M8×20 | M8×20 |

| Air filtration(mm) | 0.279 | 0.279 | 0.279 | 0.105 | 0.105 | 0.105 | 0.105 | 0.105 |

| Oil filtration | 125(μm)(120 mesh/inch) (according to customer requirements) | |||||||

| Model | EF1-25, EF2-32, EF3-40, EF4-50, EF5-65, EF6-80, EF7-100, EF8-120 |

|---|

There are no reviews yet.