Cutting Fluids & Coolant Systems

Cutting Fluid Extreme Pressure Emulsified Cutting Fluid Metal Aluminum Alloy Environmental Protection Cutting Fluid Cast Iron Cutting Fluid

Product Type: Extreme Pressure Emulsified Cutting Fluid

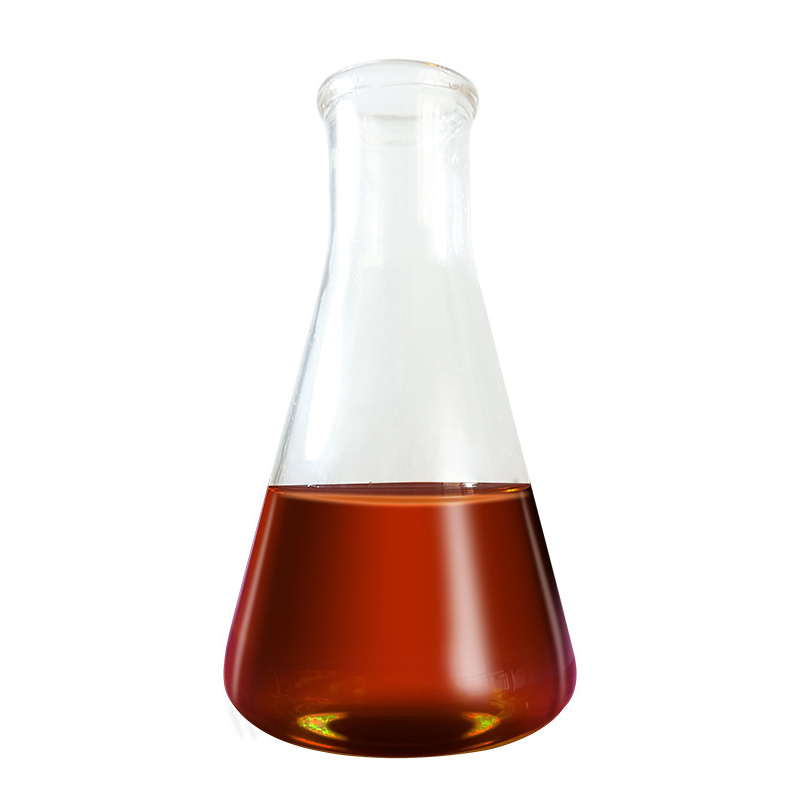

Product Appearance Raw solution: reddish brown oily liquid

Applicable processing materials: cast iron steel/aluminum/copper, etc.

Processing method: turning/milling/drilling/boring/dumpling/tapping

$138.00 – $1,036.00

CompareProduct parameters of the Extreme Pressure Emulsified Cutting Fluid

| Product Type | Extreme Pressure Emulsified Cutting Fluid |

| Product Appearance Raw solution | Reddish brown oily liquid |

| PH value of stock solution | 7.5~9.0 |

| Defoaming, mL/10min | <2 |

| 5% dilution anti-rust test (35±2°C) | Steel sheet≥24h |

| 5% dilution corrosion test (55±2°C) | Steel sheet≥24h |

| Applicable processing materials | Cast iron steel/aluminum/copper, etc. |

| Processing method | Turning/milling/drilling/boring/dumpling/tapping |

Product advantages of the Extreme Pressure Emulsified Cutting Fluid

- Long anti-rust period

During the cutting process, the workpiece is prone to rust when it comes into contact with water. The cutting fluid has a certain anti-rust performance, thereby reducing the rust of the workpiece, reducing the production process, and reducing production costs. - Good settlement

Good permeability and chip removal, so that the cutting fluid penetrates into the cutting edge in time. And ensure that chips can be discharged smoothly, so deep hole drilling cutting fluid requires extremely high extreme pressure and low viscosity. - Low foam, does not hurt hands

There is no stimulation to the human skin, avoiding redness, itching, swelling, and shedding of the skin on the hands of workers. - Resistant to corruption and odor

It adopts an environmentally friendly formula containing antibacterial ingredients, which can be used stably for a long time, will not stink and deteriorate, and prevent workers from respiratory diseases.

Application Scenario

| Volume | 18KG, 180KG |

|---|

There are no reviews yet.