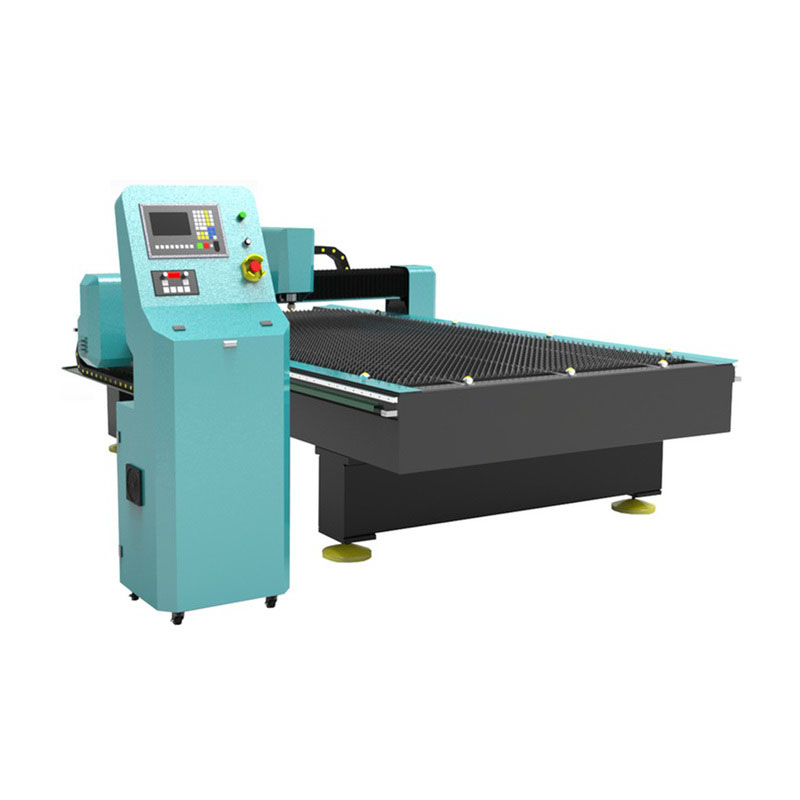

CNC Plasma Cutting Machine Top One Sale Plasma Metal Cutter

Features

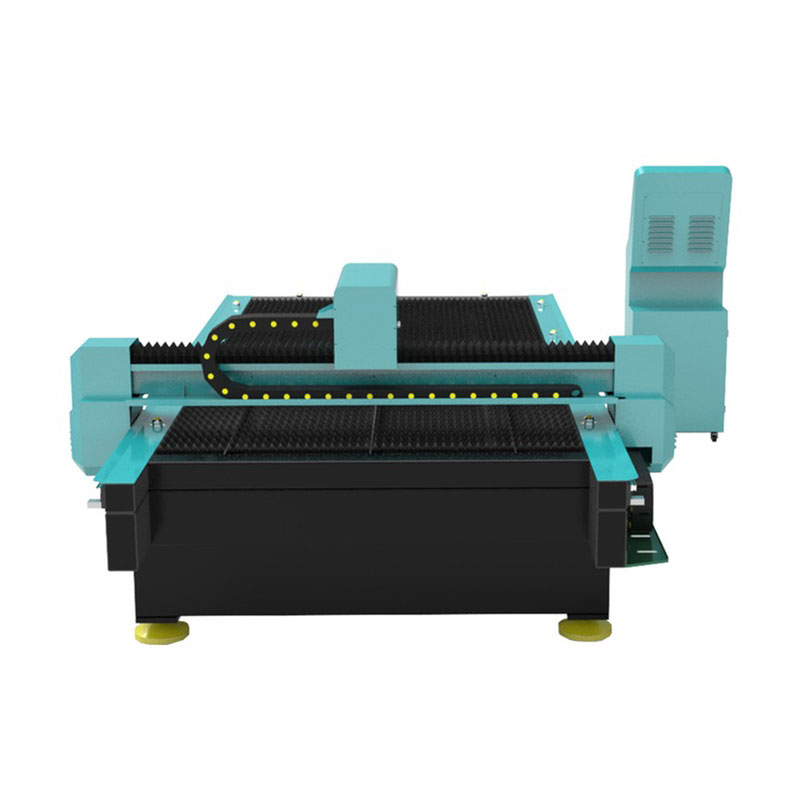

1. Welded thick-walled steel structure, after special treatment, no distortion for the whole structure high precision, and long service life time.

2. Cutting system use Beijing Starfire system/ Start system/ FLMC-2300A or DSP system; Equipped with automatic height controller (controller), which can according to your material planeness, cutting head can automatically stable, and fast adjust.

3. Taiwan linear rail, ensure vertical section, more precision.

4. Suitable software: Artcam/ Fastcam/ Starfire etc.

5. If you cut thick material, according to actual use, we’ll add water tank for you for free, to absorbs a large amount of smoke generated during cutting.

6. Machine could be customized, whatever specifications, appearance, etc. Any request you’ve, could tell us directly.

$3,800.00

Compare| Working size | 1300mm*2500mm, 100mm stroke z-axis sliding table |

| Cutting speed | 10-15m/min |

| Transmission system | 1.25m rack, square 20 linear guide and slider |

| Operating System | Starfire SF2100/DSP A12 control system |

| Driver | JMC stepper motor and driver |

| Plasma power supply | Huayuan |

| Cutting thickness | 0-30mm |

| Cutting type | Plasma/oxy-acetylene or propane |

| Input voltage | 3 phase,220v/380v±10% |

| Mode of file transfer | USB Interface |

| Water tank | Underlay stainless steel sink(absorb smoke and prevent burning) |

| Table-board | sawtooth + square pipe, spacing is 70 mm |

| Straight line positioning precision | ±0.2mm/10m |

| Straight line repeat precision | ±0.3mm/10m |

| Environmental temperature | -5~45°C |

| Humidity | <90% No concreting |

Based on 0 reviews

Be the first to review “CNC Plasma Cutting Machine Top One Sale Plasma Metal Cutter” Cancel reply

Related products

-

Plasma Cutting Machines

Popular Air Plasma Cutting Machine For Sale

0 out of 5(0)100% (40° C) duty cycle, suitable for long time, heavy load, high temperature and bad circumstances

Current up-slope function: Reduce the impact on striking arc and decrease consumption of cutting torch parts

Air pressure, hydraulic pressure sensor: Protect torch from being burnt efficiently

Arc striking signal, arc pressure signal, air supply control and arc pressure output function , suitable for CNC and robot cuttingSKU: n/a$1,290.00 -

Plasma Cutting Machines

CNC plasma cutting machine High precision cutter Best Selling in America

0 out of 5(0)Materials

Applied for mild steel plate,aluminum plate,galvanizing plate,titanium plate and so on.Industry

Generally used in engineering machinery/ shipbuilding industry, shape cutting of thick plate, rivet weld industry and steel plate blanking.SKU: n/a$6,299.00 -

Plasma Cutting Machines

CNC Plasma Cutting Machine Portable 1500*3000mm

0 out of 5(0)Big size Track

Use high precision linear guide, and light weight alloy-aluminum horizontal rail, not easy become deformation.Fine Cutting torch

Flame cutting torch is fixed, plasma cutting torch is mobile type.

Flame torch and plasma torch could be changed very easily.SKU: n/a$1,650.00 -

Plasma Cutting Machines

Plasma Cutting Machine Metal Sheet Stainless Steel Plate Cutting CNC Plasma Cutter

Plasma Cutting Machines

Plasma Cutting MachinesPlasma Cutting Machine Metal Sheet Stainless Steel Plate Cutting CNC Plasma Cutter

0 out of 5(0)Application of plasma cutting machine:

Advertising industry:

Advertising signs, logo making, decorative products, production of advertising and avariety of metal materials.

Metal industry:

For steel, Carbon Steel, Stainless steel, alloy steel, spring steel, copper plate, aluminium plate,gold, silver, Titanium and other metal plate and tube.SKU: n/a$6,250.00

There are no reviews yet.