CG wholesale high quality horizontal electric stainless steel heavy fuel oil transfer screw pump,Supply high viscosity corrosion resistant stainless steel screw pump

CG stainless steel screw pump (honey delivery pump) is a new type of internal meshing rotary positive displacement pump. It has the advantages of high efficiency, strong self-priming ability, and wide application range. It can be used to transport various media that are difficult to transport. Therefore, stainless steel screw pumps are called universal pumps abroad. The pump can transport neutral or corrosive liquids, clean or abrasive liquids, liquids containing gas or prone to bubbles, liquids with high or low viscosity, including liquids containing fibrous and soft substances.

$560.00

CompareProduct introduction

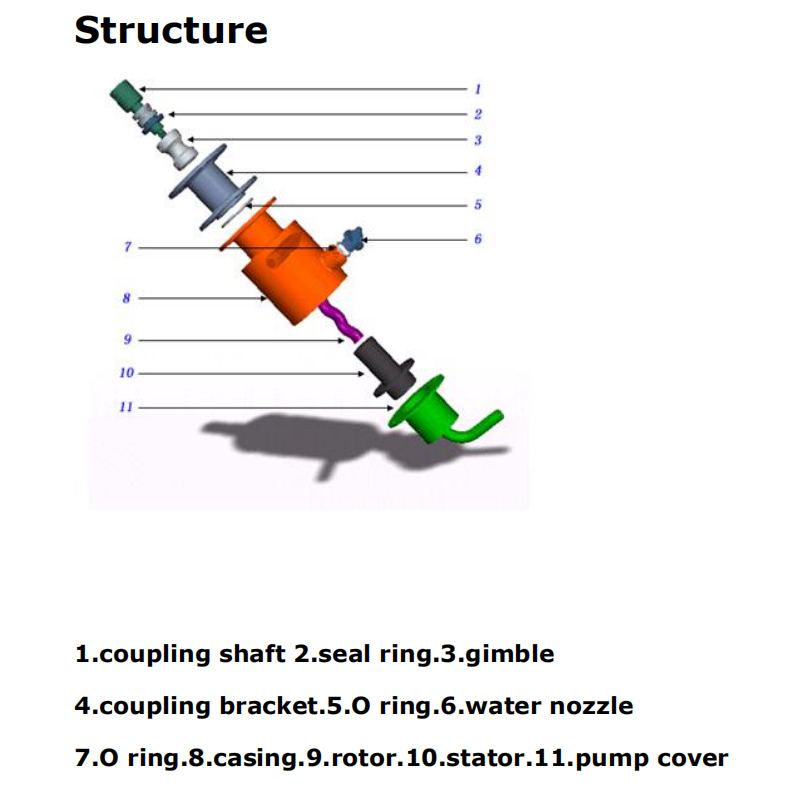

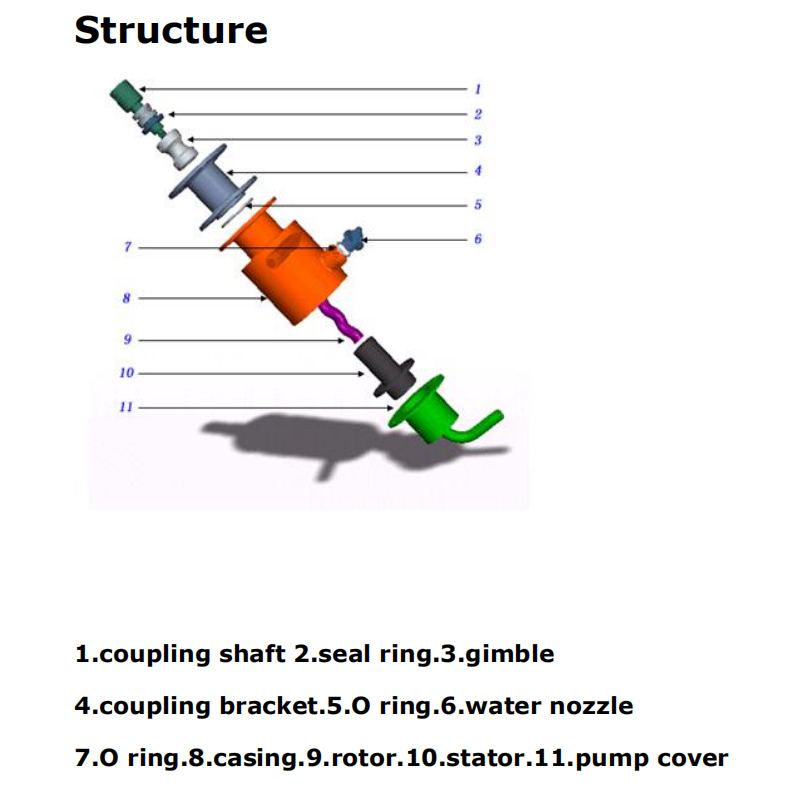

The CG stainless steel screw pump is a new internal toothing rotary positive displacement pump,which has such advantages as high efficiency, strong self-priming capacity and wide application scope. It can transportvarious media which are hard to transport. Therefore,the stainless steel screw pump is called a universal pump in foreign countries.

Application

It can transport liquids which are neutral, corrosive, clean or grindable, contain gases or are vulnerable to producing gases, are high-viscosity or contain fibers or soft substances.

|

Flow rate

|

up to 5 m³/h

|

|

Head

|

up to 50 m

|

|

Speed

|

max 1400 rpm

|

|

Temperature

|

max 140 ℃

|

|

Casing pressure

|

low pressure

|

|

Shaft seal

|

mechanical sealing

|

|

Material

|

Stainless steel

|

|

Symptoms

|

cause

|

Solution

|

|

after startup

no liquid

|

1. There is a lot of air inhalation

2. The motor turns incorrectly

3. The viscosity of the feed liquid is too high

|

1. Check whether the liquid level at the suction port is too low and whether there is air leakage in the suction pipe

2. Adjust any two-phase incoming line of the motor

3. Diluent material

|

|

The pump has a large vibration or noise

|

1. There is a large amount of air mixed with the suction liquid in the pump

|

1. Check the liquid level of the feed liquid and try to remove the air in the suction liquid

|

|

During operation,

Significant drop in traffic

|

1. The bushing is worn and the gap increases

2. Speed reduction

3. The universal joint or the shaft is damaged and fails to move

4. The depth of the suction pipe intruding into the liquid is not enough, and air enters the pump

5. The universal joint is broken

|

1. Replace the bushing and replace the screw if necessary

2. Check the power supply and motor

3. Stop for maintenance, replace the universal joint or the shaft

4. Reduce the suction height, increase the penetration depth, and eliminate the air in the suction liquid

5. Replace the universal joint

|

|

electric motor

overload

|

1. The head exceeds the head of the pump too much

2. The viscosity of the material liquid is too high

3. The voltage is too low

|

1. Minimize the head loss of the pipeline or replace the high-lift pump

2. Dilute feed liquid

3. Check the reason and increase the voltage to the specified value

|

There are no reviews yet.