Bottling Line

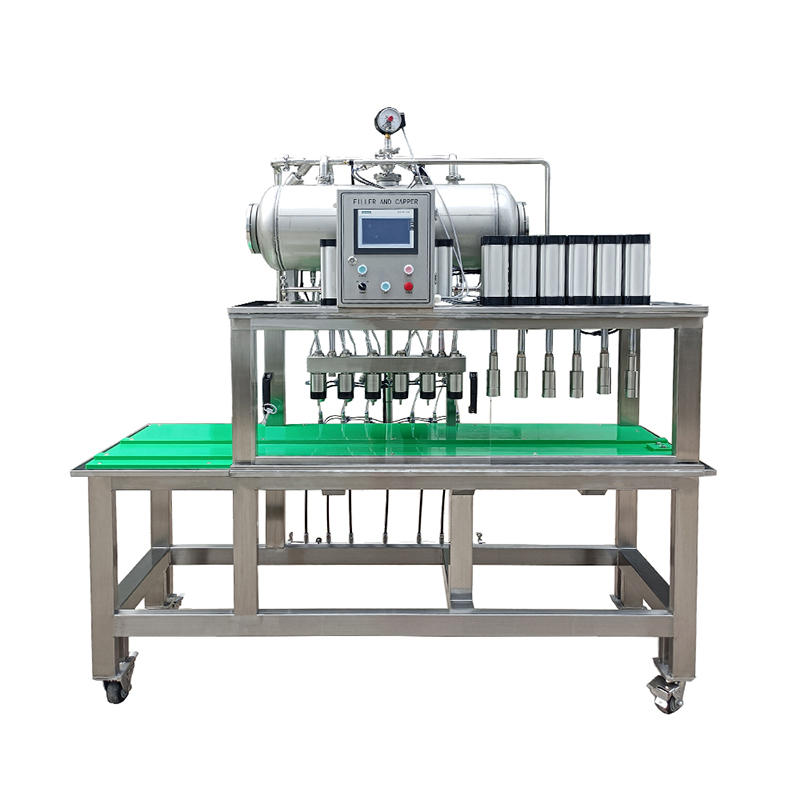

8 Heads Beer Bottle Filling and Capping Machine Semi Automatic Beer Glass Bottle Filling Machine Drink Filling Equipment Bottling Line

- Automatic control by PLC, all parameters can be adjusted.

- Filling and capping process can be finished in this machine at one time.

- With CO2 pressurization and vacuumization function

- Adopt isobar filling method and with unique pressure maintaining system,performance stable and reliable, beer loss minimum.

- With pressure compensator, to guarantee a stable filling process.

NOTE: Prices may vary by product model and material.

$9,600.00

CompareWorking process of Beer Bottle Filling and Capping Machine

Fix the bottles–CO2 Purge–CO2 pressurizing–CO2 Purge–CO2 pressurizing–filling–pressure stabilization–pressure relief–stop–move the bottles to the capping stations–capping–take the bottles

| Equipment Outer Dimensions | 1800*800*2400mm |

| Net Weight | 300KG |

| Production Capacity | 300-500 bottles/Hr |

| Applicable Bottles | 330ml-2L |

| Working Stations | 4-10 |

| Power Supply Voltage | AC 380V 50HZ (customized) |

Main function and feature

- Automatic control by PLC, all parameters can be adjusted.

- Filling and capping process can be finished in this machine at one time.

- With CO2 pressurization and vacuumization function

- Adopt isobar filling method and with unique pressure maintaining system,performance stable and reliable, beer loss minimum.

- With pressure compensator, to guarantee a stable filling process.

There are no reviews yet.