Portable handheld induction sealing machine 20mm-130mm 110V induction sealing machine white bottle cap sealing machine, handheld large-caliber honey glass bottle plastic bottle tin foil gasket aluminum foil sealing machine,filling capping

- Induction sealing Machine:It is a non-contact heating process that accomplishes the hermetic sealing of a container with a closure that includes a heat-sealable aluminium foil laminate.

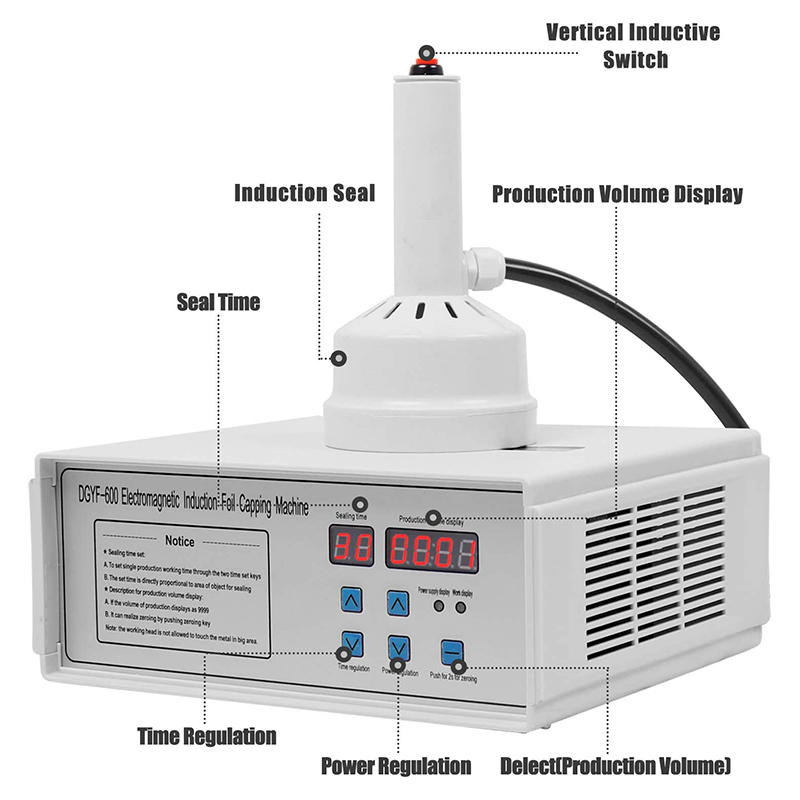

- Digital Display: Setup the sealing time and output power according to different sizes of bottle caps.Visible production volume indication,much more convenience for small and medium workloads.

- Auto safety protection: Electromagnetic induction sealer have the automatic overheating,over voltage,over current protection function.

- Easy to operate:Cover the bottle with inductive film(Surface with aluminum foil), then press the inductive switch,you are done for sealing.

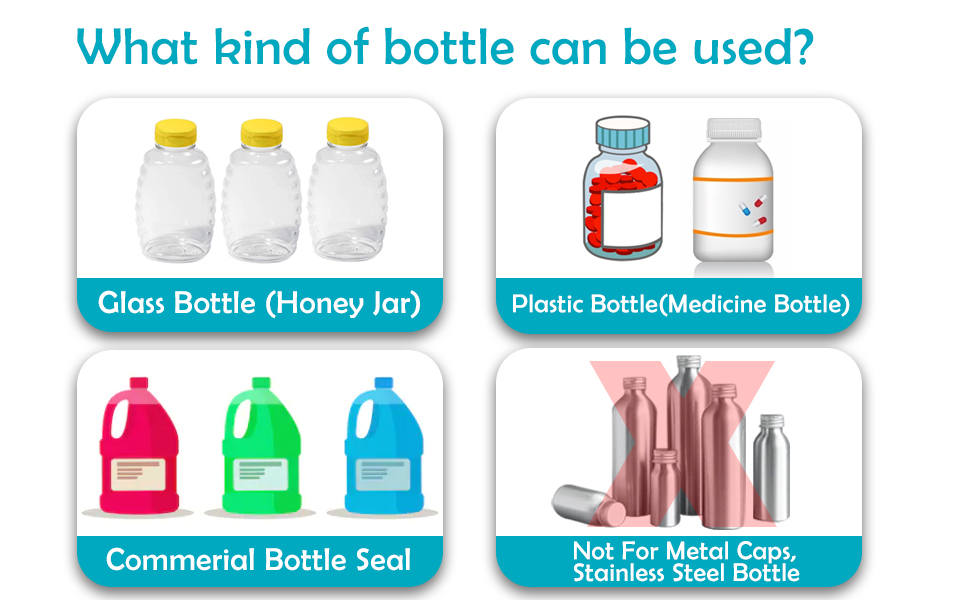

- Widely use:Applied to the sealing of non-metallic containers such as plastic bottles and glass bottles on the market, like ABS, PE(HDPE, LDPE), PET, PP, PS, PVC.

$357.00

CompareHandheld Heat Sealing Machine for Plastic Glass Bottles

Feature

- Applies up to 20 seals per minute.

- Digital timer ensures accurate sealing.

- Automatic overheat self-protection.

- Suitable for small and medium workloads

- Widely used in pharmaceutical, chemical, food, beverage, cosmetics and other industries.

Specification

Dimension:310*260*130(mm)

Voltage: 110V

Output Power: ≤500W

Static Power Consumption:≤2A

Casing protection degree: Ip20

Yield counting range: 0-9999

Work Frequency: 50Hz-80Hz

Sealed Diameter:Φ20~Φ100(mm)/Φ20~Φ130(mm)

Relative Humidity(RH):≤95%

Container height: Unlimited

How Cap Sealing Works

- The induction sealing process involves an induction current being applied to a aluminum liner in a plastic cap.

- First, The cap already has the liner inside. The liner contains the sealing material adhered to a foil layer.

- Secondly,Place sealing wand over the cap and press the button.The induction current heats the foil liner, melting the sealant.

- After the sealing process, the entire liner will be completely removed from the cap, it adheres to the bottle.

Based on 0 reviews

Be the first to review “Portable handheld induction sealing machine 20mm-130mm 110V induction sealing machine white bottle cap sealing machine, handheld large-caliber honey glass bottle plastic bottle tin foil gasket aluminum foil sealing machine,filling capping” Cancel reply

Related products

-

Beer Keg, Packaging Machines

30L European Standard Beer Keg Stainless Steel Beer Barrel Full Type of Beer Spear Connector Draft Beer Brewing equipment Keg

Beer Keg, Packaging Machines

Beer Keg, Packaging Machines30L European Standard Beer Keg Stainless Steel Beer Barrel Full Type of Beer Spear Connector Draft Beer Brewing equipment Keg

0 out of 5(0)- Product name:European standard 30L

- Product size:Diameter 408* height 365mm

- Product capacity:30L

- Product weight:9.3KG+5%

- Product material:304 stainless steel

NOTE: Prices may vary by product model and material.

SKU: n/a$72.00 -

Beer Keg, Packaging Machines

20L European Standard Beer Keg Stainless Steel Beer Barrel Full Type of Beer Spear Connector Draft Beer Brewery equipment Keg

Beer Keg, Packaging Machines

Beer Keg, Packaging Machines20L European Standard Beer Keg Stainless Steel Beer Barrel Full Type of Beer Spear Connector Draft Beer Brewery equipment Keg

0 out of 5(0)- Product name:European standard 20L

- Product size:Diameter 395* height 285mm

- Product capacity:20L

- Product weight:7.0KG+5%

- Product material:304 stainless steel

NOTE: Prices may vary by product model and material.

SKU: n/a$66.00 -

Keg Washing Machine, Packaging Machines

Stainless steel beer draft beer Keg washing machine, keg filling and cleaning equipment, beer keg cleaning tools

Keg Washing Machine, Packaging Machines

Keg Washing Machine, Packaging MachinesStainless steel beer draft beer Keg washing machine, keg filling and cleaning equipment, beer keg cleaning tools

0 out of 5(0)Beer keg cleaning factory cleaning settings

Put the barrel and press it – discharge residual liquid – hot water cleaning – air flushing (draining clean water) – hot alkaline water cleaning – air flushing (alkaline water cycle) – hot clean water cleaning – air flushing (clean water draining) – acid cleaning – air flushing ( Acid liquid circulation)-hot water cleaning-air flushing (draining clean water)-C02 air flushing (draining oxygen in the barrel)-C02 backup pressure-stop (take the barrel)SKU: n/a$7,860.00 -

Capping Machines, Packaging Machines

Desktop electric bottle cap capping machine, bottle cap capping locking 220V, semi-automatic capping machine, automatic capping machine for beverage mineral water,wine bottle capper

Capping Machines, Packaging Machines

Capping Machines, Packaging MachinesDesktop electric bottle cap capping machine, bottle cap capping locking 220V, semi-automatic capping machine, automatic capping machine for beverage mineral water,wine bottle capper

0 out of 5(0)- Power supply: AC 220V, 50/60Hz

- Working ways: electric screw capping

- Screw cap diameter: φ10 – φ50mm

- Machine size: 520 * 300 * 530mm

SKU: n/a$1,569.00

There are no reviews yet.