Automatic Pneumatic Conveyor Vacuum Feeder For Rice Flour Powder Granule

The vacuum feeder is equipped with a compressed air back flushing device. Each time the material is discharged, the compressed air pulse back flushing the filter, and the powder adsorbed on the surface of the filter is dropped to ensure the normal operation of the suction.

For the vacuum feeder with material level control, the material in the hopper of the receiving equipment is automatically fed through the material level controller.

When the hopper of the receiving equipment is higher than a certain position, the vacuum loading machine stops feeding.

When the material level is lower than a certain position, the vacuum loading machine automatically starts to complete the feeding of the receiving equipment.

$1,875.00

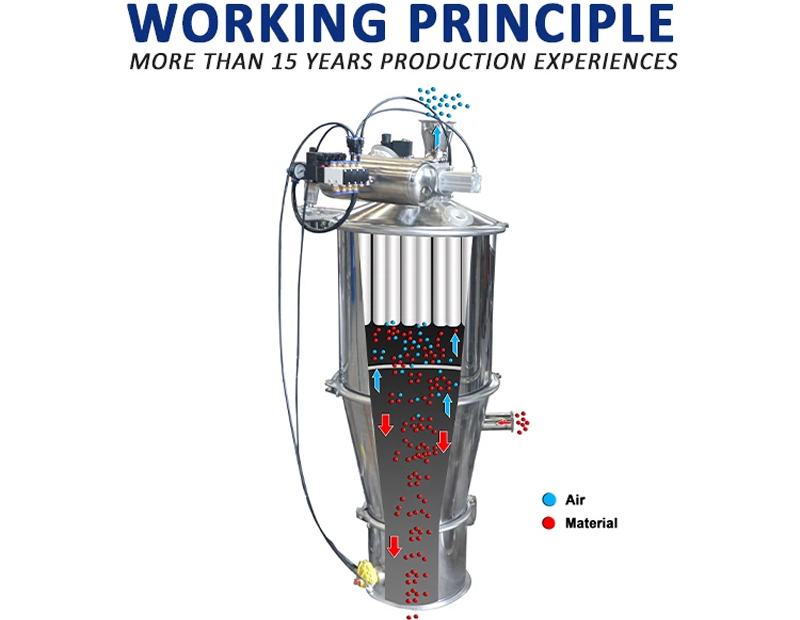

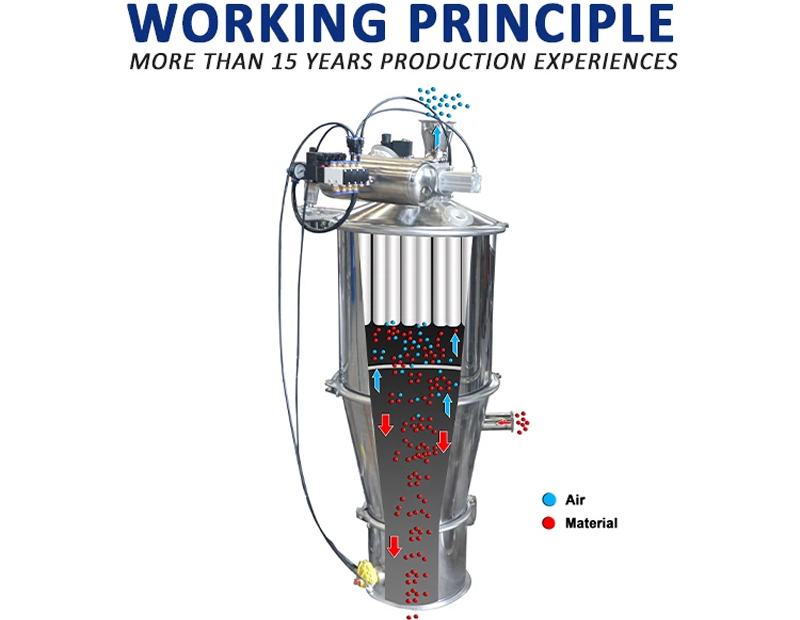

CompareWorking Principle of the Pneumatic Conveyor

- The vacuum feeder uses a vacuum pump to suction the air, so that the inlet of the suction nozzle and the whole system are in a certain vacuum state.

- The powder particles are sucked into the nozzle along with the outside air to form a gas stream, which passes through the suction pipe and reaches the hopper in the hopper.

- Gas and material separation.

- The separated material enters the receiving equipment.

- The feeding and discharging are completed by continuously opening and closing the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is

- controlled by the control center.

Product advantages

- BACK BLOWING DUST REMOVAL DEVICE

Adopts pneumatic removing dust device, low energy consumption, low noise and convenient control. - FILTER

Different materials can choose as client’s demand, can well filtering dust. - VORTEX AIR PUMP

The vortex air pump is used as power, which is oil-free, water-free and maintenance-free. - ROTATING CYLINDER

The entire conveying process is completed in a completely closed state, eliminating dust pollution.

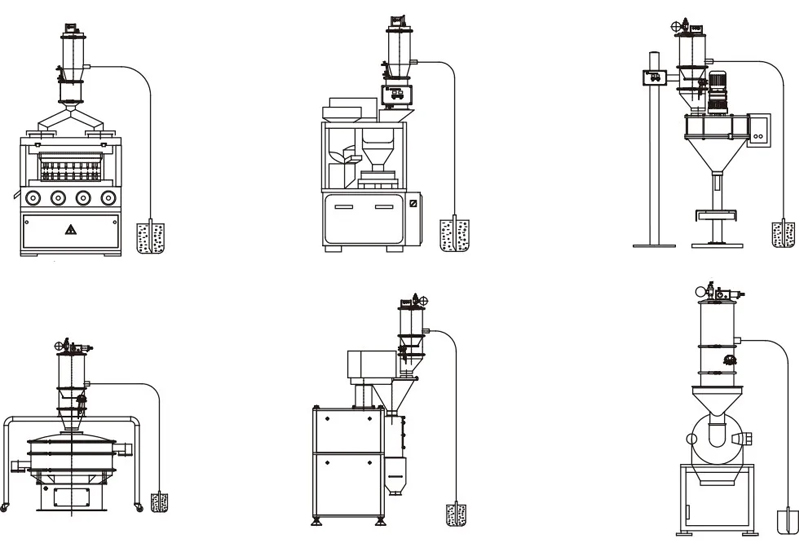

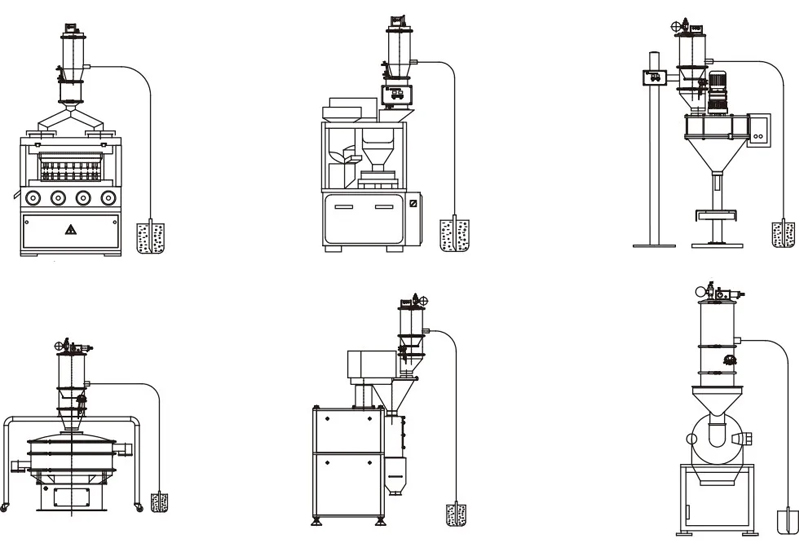

Application Scale of Vacuum feeder

Vacuum conveyors can be widely used in magnetic materials industry, food processing industry, plastic processing industry, lithium power industry, coatings industry, chemical industry and pharmaceutical industry etc.

Based on 0 reviews

Be the first to review “Automatic Pneumatic Conveyor Vacuum Feeder For Rice Flour Powder Granule” Cancel reply

Related products

-

Pneumatic Conveying Equipment/Pneumatic Conveyor

Pneumatic Vacuum Feeder Portable Vacuum Conveyor For Powder

Pneumatic Conveying Equipment/Pneumatic Conveyor

Pneumatic Conveying Equipment/Pneumatic ConveyorPneumatic Vacuum Feeder Portable Vacuum Conveyor For Powder

0 out of 5(0)Features:

The electric vacuum feeder is a new product developed on the basis of extensive absorption of similar foreign products. At present, it is the most advanced, ideal and complete vacuum conveying equipment for powder, granular, and powder-grain mixtures in China. It reduces the labor intensity of workers and solves the problem of dust spillover during feeding.SKU: n/a$3,900.00 -

Pneumatic Conveying Equipment/Pneumatic Conveyor

Pneumatic Conveying Equipment Hose Grain Suction Machine

Pneumatic Conveying Equipment/Pneumatic Conveyor

Pneumatic Conveying Equipment/Pneumatic ConveyorPneumatic Conveying Equipment Hose Grain Suction Machine

0 out of 5(0)Note: When the grain suction machine is working, the bending radius of the pipe must not be less than 1.2 meters, and the pipe must not be squeezed or damaged by sharp objects to cause denting and deformation.

MOQ:10PCS

SKU: n/a$650.00 -

Pneumatic Conveying Equipment/Pneumatic Conveyor

Industrial Automatic Conveyor Grain Powder Feeding Conveying Machine Pneumatic Vacuum Conveyor

Pneumatic Conveying Equipment/Pneumatic Conveyor

Pneumatic Conveying Equipment/Pneumatic ConveyorIndustrial Automatic Conveyor Grain Powder Feeding Conveying Machine Pneumatic Vacuum Conveyor

0 out of 5(0)Application of pneumatic conveyor system

Vacuum Conveyor is the most advanced, perfect vacuum conveying equipment of powder material, granular material, and powder-granular mixture. It can automatically transport a variety of materials to mixing machines, packing machines, injection molding machines, grinders, etc. With the advantage of cost reduction and no powder pollution.SKU: n/a$3,850.00 -

Pneumatic Conveying Equipment/Pneumatic Conveyor

Rice Husk Lifting Pneumatic Conveying Machine Grain Suction Machine Pneumatic Loading And Unloading Equipment

Pneumatic Conveying Equipment/Pneumatic Conveyor

Pneumatic Conveying Equipment/Pneumatic ConveyorRice Husk Lifting Pneumatic Conveying Machine Grain Suction Machine Pneumatic Loading And Unloading Equipment

0 out of 5(0)Applicable Industries

Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food and beverage Factory, Farms, Restaurants, Home Use, Retail, Food Shop, Printing Shops, Construction works, Energy and Mining, Food and beverage Shops, Advertising CompanySKU: n/a$31,250.00

There are no reviews yet.