Laminating Machines

Automatic/Manual Laminating Machine 0-10 Meters/Min Cold Laminator Machine Heat Assisted & Trimmer

Scope of application

Used in hot laminating and cold laminating of large format materials such as indoor and outdoor photo advertisements, car stickers, graphic printing, photo studio imaging, screen printing, X display racks, PVC boards, KT boards, etc. Plates, glass, profiles, acrylic, wooden doors, etc. Surface protective coating.

- Only one person is required to operate, reducing labor costs.

- Heating to 60 degrees for cold mounting can completely avoid bubbles and snowflakes.

- The laminating efficiency is high, the yield is high, and the lamination of the entire 50-meter roll does not go skew.

- Automatically peel off the bottom paper.

- The film material tension adjustment system enables the cold lamination film to have good expansion force and reduces the risk of wrinkles in the film.

$2,305.00

CompareTechnical Parameters of the Laminating Machine

| Motor power | 60W |

| Heating power | 1500W |

| Laminating temperature | 0℃-60℃ |

| Applicable film thickness range | 10-250μm |

| Preheating time | 0~10 minutes |

| Laminating width | ≤1580mm |

| Laminating speed | 0-10m/min |

| Laminating material thickness | 50mm |

| Speed gear control | infinite |

| Large roll film outer diameter | 200mm |

| Film roll paper tube inner diameter specifications | 2.25 inches, 3 inches |

| Rubber roller lifting height | 50mm |

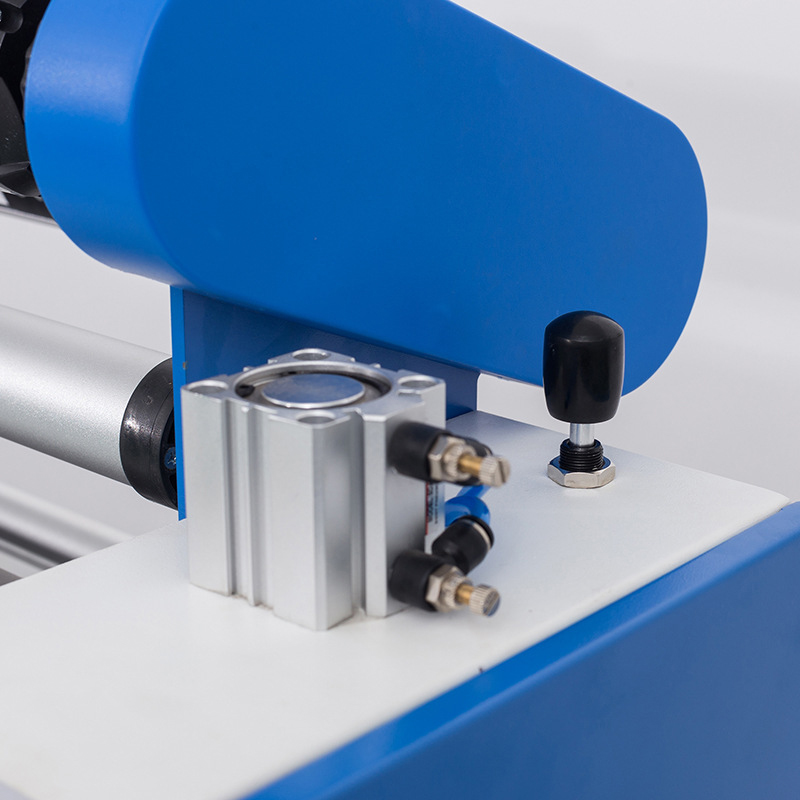

| Pressure adjustment method | Manual |

| Automatic film peeling and rewinding backing paper device | Motor |

| Rubber roller diameter | 130mm |

| Weight | 210kg |

| Product dimensions (L×W×H) | 1980mm×570mm×1240mm |

| Packaging size (L×W×H) | 2090mm×620mm×680mm |

Features

- Manual lamination and automatic lamination can be switched at any time, easy to use;

- Original post-loading film lamination method, easy to operate;

- Infrared temperature control, no damage to the rubber roller, more temperature control;

- Unilateral linkage, easy lifting and lowering;

- Stepless speed adjustment function;

- With reversal function;

- Only one person is required to operate, reducing labor costs;

- Heating to 60 degrees for cold mounting can completely avoid bubbles and snowflakes;

- The laminating efficiency is high, the yield is high, and the lamination of the entire 50-meter roll does not go skew;

- Automatically peel off the bottom paper;

- The film material tension adjustment system enables the cold lamination film to have good expansion force and reduces the risk of wrinkles in the film.

There are no reviews yet.