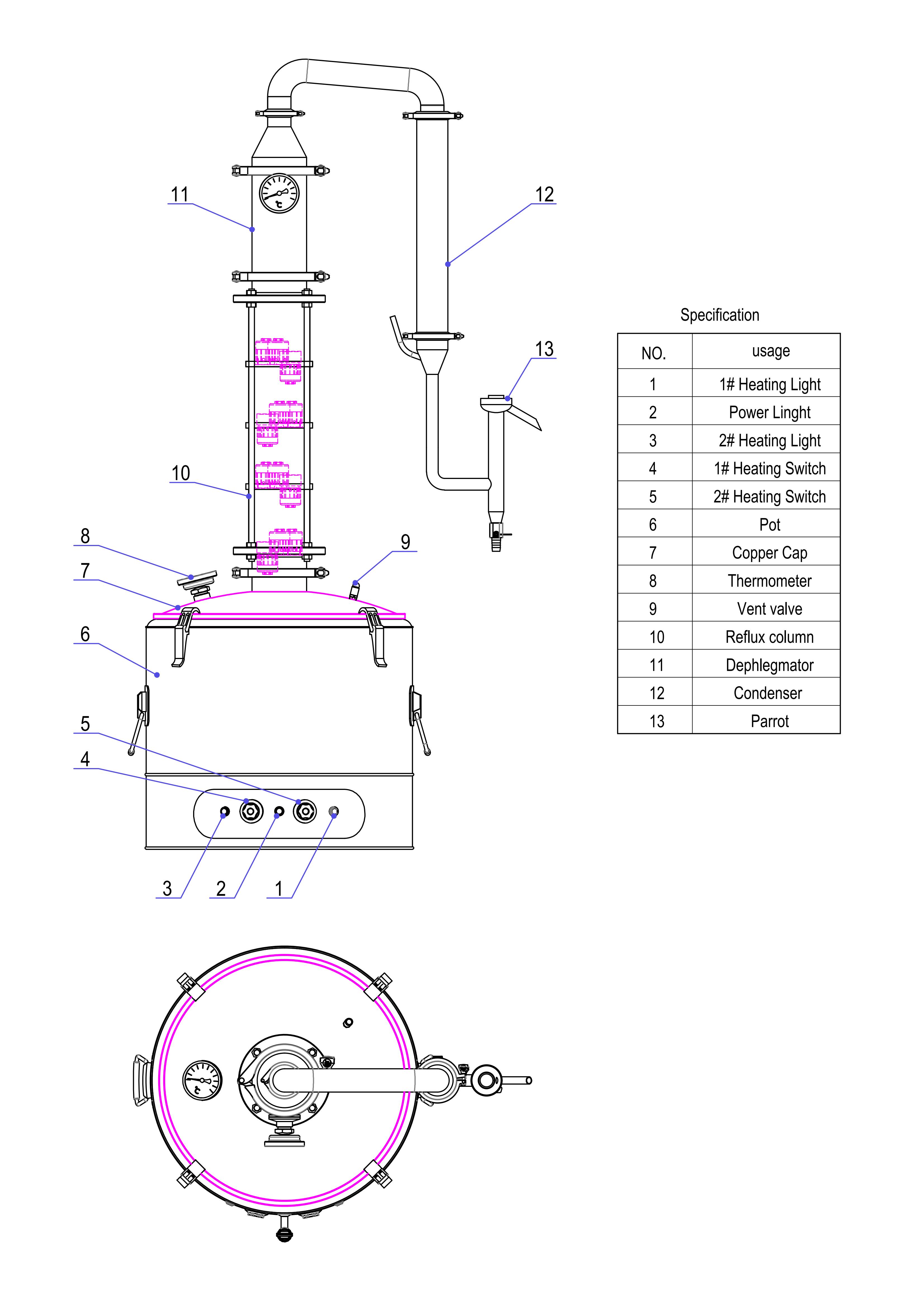

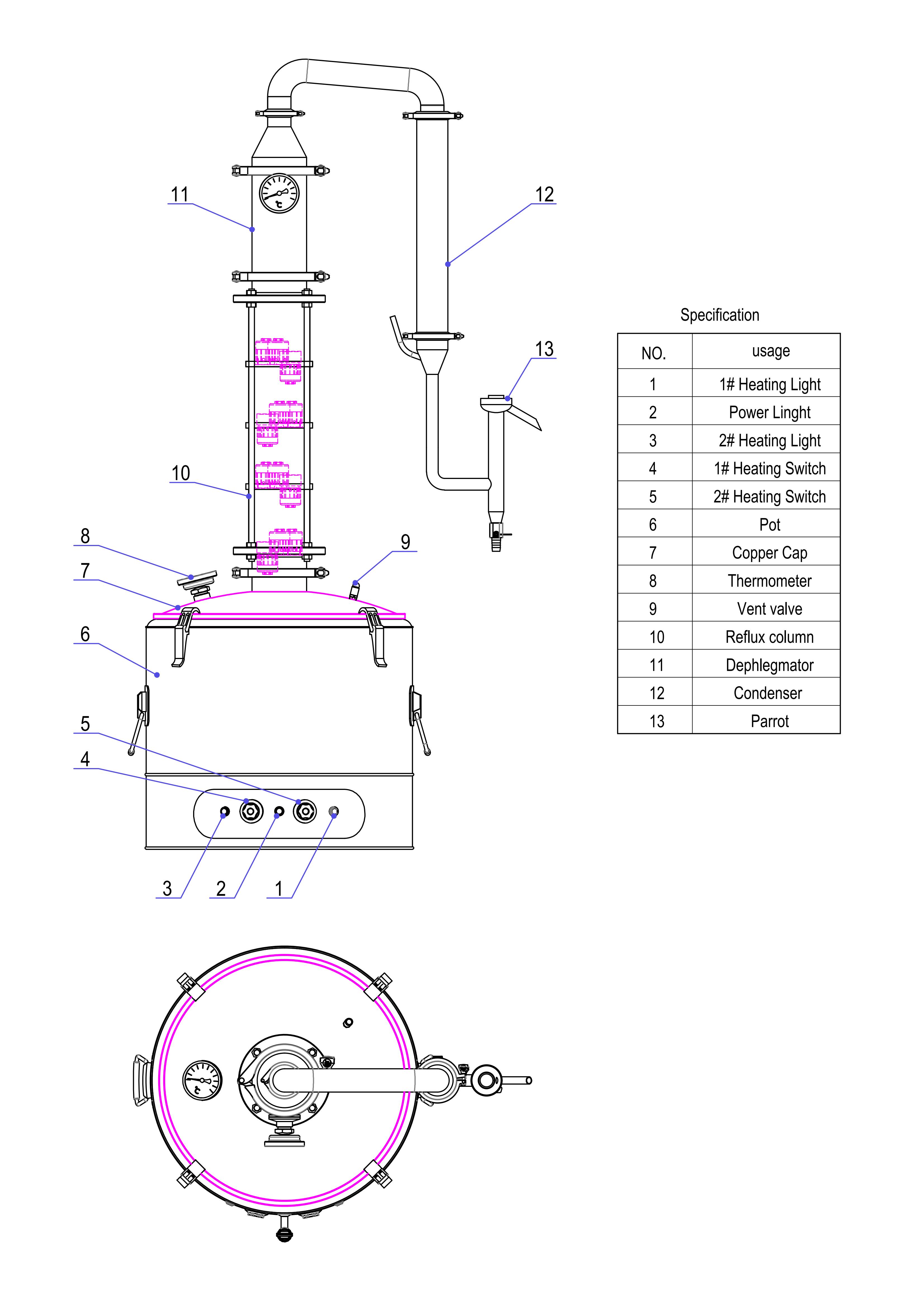

30L 8 Gallon Distilling Equipment Fermenter Copper Still with Heating Device Sight Glasses Wine Making Kit for DIY Whisky Wine Brandy Gin

Compare

1.Quality Assurance: This fermentation tank is made of food-grade 304 stainless steel and pure copper, a wear-resistant and anti-oxidation materials, and has a stunning appearance after the thickening treatment and polishing.

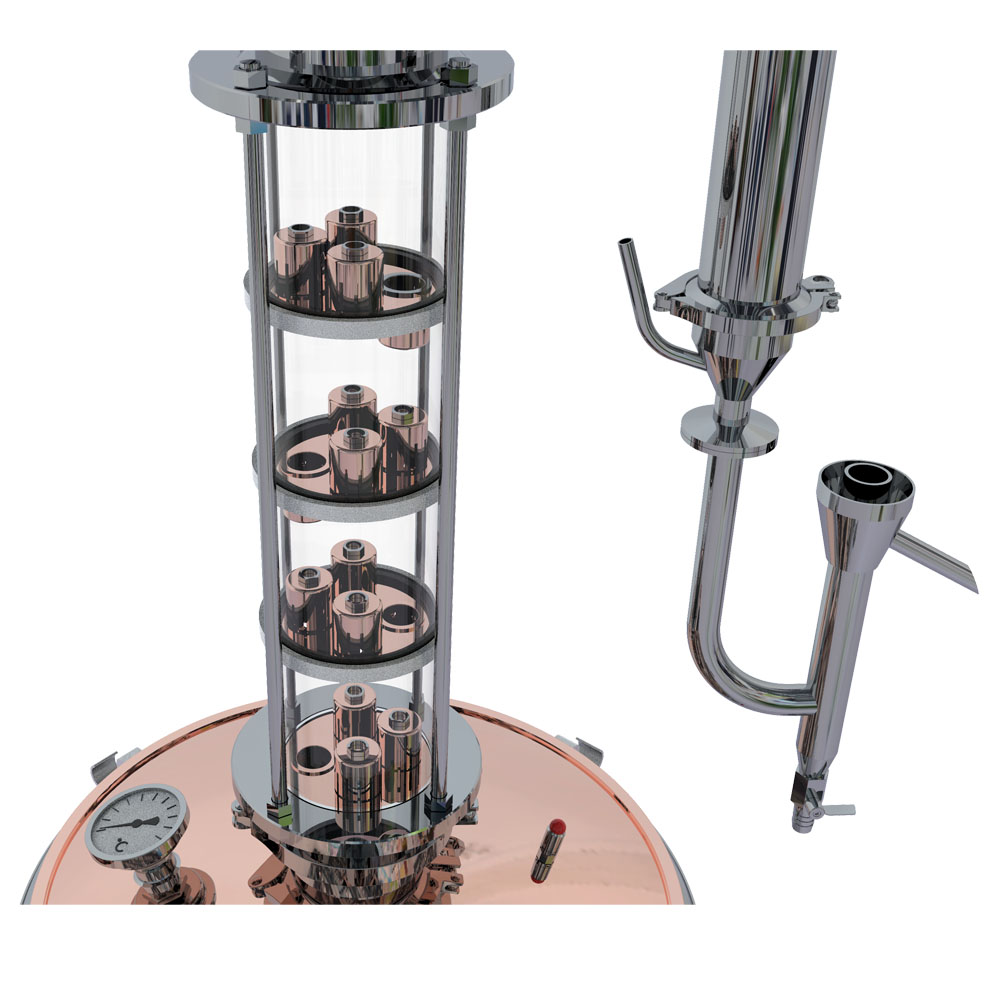

2.Unique Features:Four-story meticulous distillation pylon with sight glass, exclusive function-“Spirit Dance” can be seen clearly. The liquor vapor fully reacts with the pure copper tower core, distilling layer by layer, effectively remove methanol and accurately remove fusel oil. Making limpidity wine and smooth taste.

3.Excellent Performance:Powerful Distillation Function-“Spirit Dance”, locking impurities wine, pure copper can be combined with sulfide, accelerate the emission of low-boiling substances, raise low-concentration liquor vapor molecules to high-concentration in the column. Eliminating sulfide in wine, quick removal of methanol/formaldehyde and accurately remove fusel oil. Greatly improve wine quality, limpidity wine.

4.Sufficient Capacity:Our Electric Alcohol 30L (8Gal) is able to distill a great deal of raw material by heating to selectively boil and then cooling to condense the vapor, meet different distillation needs of customers.

5.Versatile Application:Depending on your preference, you can make different kinds of wine in the electric copper distiller, such as grain liquor, rice wine, whiskey, brandy, fruit wine, grape wine, etc.

[Safety]

Using this still involves working with heat, steam, electricity, gas, and possibly explosive vapors. You must take extreme care to prevent injury, fire, or explosion if you ever decide to use the device.

Some view using it to distill alcohol as being akin to boiling gasoline on your home gas or electric stove. Over time more than one person has been maimed or killed in the explosions and fires resulting from these activities. You must be careful at every step in these procedures.

[Initial Checkout]

In this section we will be going over how to operate the still for the first time. Before you use the still for any purpose, test the apparatus by distilling a gallon or two of water. This preliminary run will verify that the joints don’t leak, that there is sufficient heat input to do the job, and that there is enough cooling to control the distillation. It will also help clean up any remaining flux from the joints soldered during construction.

[The Internal Reflux Still]

To start the run, mount the boiler on top of the heat source, fill it with about a gallon of tap water, and attach the column to the boiler. Then connect the cooling hoses on the column to the water supply and drain.

Do not allow the cooling water to circulate through the apparatus at this time.

[Initial Startup]

Turn on the heat to its highest setting and insert the thermometer in the top of the column. The bulb should be seated to the level of the upper column tee connection (where the vapors flow to the condenser).

In a short time (about 10 or 15 minutes depending on the heat source) the water should be boiling to the point where both vapor and liquid can be seen exiting the condenser. The thermometer should indicate that the boiling point temperature (100° C.) has been reached in the column.

The next step should be to determine the maximum distillation rate of the still. To do this you will need to open the cooling flow to the maximum and increase the boiling rate to the point where the condenser can no longer condense all the vapor.

It’s easy to recognize this point because you’ll be able to see a lot of steam mixed in with the distillate running from the still.

When you’ve reached that point slowly back down the heat to the point where the vapors no longer exit the condenser. In doing this, be careful not to reduce the heat to the point that the thermometer drops below the boiling point (100° C.). You should now be at the maximum distillation rate settings for this still.

When you have reached that point, measure the time needed to collect exactly 250 ml of distillate.

Knowing the maximum distillation rate is important because it forms the basis for estimating the reflux flow. Recognize though, that in this exercise we are working with water. Different mixtures in the pot will have different distillation temperatures and different rates of distillate flow. You will need to redo this exercise to get the right basis figures for the distillation at hand.

Before finishing up the initial run you might find it worthwhile to time and measure a few distillate volume readings at different cooling settings to get a feel for the control sensitivity and distillation rates. Finally distill about a gallon of water to finish cleaning out the still.

[Shutdown]

When it’s time to shut the internal reflux system down you should always follow a set sequence of actions in order to avoid problems. The shutdown sequence is:

1. First remove the thermometer cap from the top of the column.

Use gloves, it may be hot.

2. Next turn off the heat.

3. Finally shut off the cooling water circulation.

This is important, because if you are using plastic tubing to collect the distillate from the condenser, it could get kinked or obstructed in some way. That would seal off the apparatus from the air. If this happened while it was cooling down, a vacuum would be formed within the still as the vapors inside condense, and the air pressure outside could crush the unit.

When the unit has reached room temperature, disconnect the cooling hoses, and back-flush the column with water. Then remove the cover and clean and flush the boiler.

There are no reviews yet.