CNC handle BT40 ER32 chuck CNC machining center high-precision handle dynamic balance

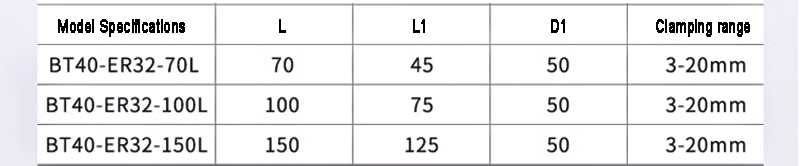

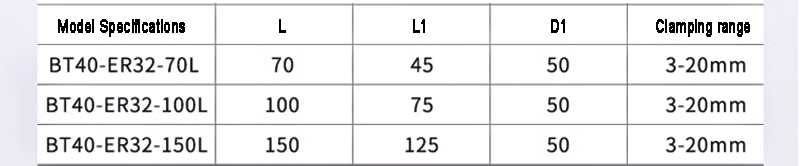

Model specification: BT40-ER32-100L

Clamping length: 100

Effective clamping length: 75

Nut outer diameter: 50

Clamping range: 3-20mm

$6.30

CompareThe inside and outside of the tool handle are integrally formed, finely controlled processing, more stable performance, and more suitable for high-precision machine tool processing.

All tool handles are fully inspected, and the detector made by Daibo Company in Germany is used to ensure that the taper of each product is 7:24, and the outer taper meets the accuracy ≤ AT3, with exquisite appearance and better quality.

The inner hole is finely ground. The collet fits precisely with the shank, so that the clamping force of the tool is greater, the rigidity is stronger, the cutting speed is faster, and the processing efficiency is improved.

With dynamic balance setting, the speed can reach 25,000-30,000 rpm, the processing hours are more stable and the precision is higher

High, small vibration, suitable for high-speed processing.

Alloy steel, the use of anti-seismic Kaixuan alloy steel can also effectively suppress vibration and is superior in anti-seismic.

Using carburizing and quenching process, the surface hardness is high, fatigue resistance and high wear resistance, and the core has the strength and toughness of low carbon steel after quenching, so that the handle can withstand certain impact and load.

Name: ER High Precision Tool Holder

Material: 40CR steel

Model: BT40-ER32-100L

Features: 40CR steel, high hardness, full product inspection, full bright appearance, exquisite workmanship, Taiwan quality, one-time clamping, one-time internal and external molding, high concentricity

Based on 0 reviews

Be the first to review “CNC handle BT40 ER32 chuck CNC machining center high-precision handle dynamic balance” Cancel reply

Related products

-

CNC Machines, Metal Machine Tool Industry

CNC cutting machine,Portable cutter,High precision cutting machine,CNC plasma cutting machine

CNC Machines, Metal Machine Tool Industry

CNC Machines, Metal Machine Tool IndustryCNC cutting machine,Portable cutter,High precision cutting machine,CNC plasma cutting machine

0 out of 5(0)The portable CNC cutting machine is a telescopic arm structure. The chassis and cantilever are made of aluminum alloy materials. It can be equipped with flame or plasma cutting. It is a high-efficiency and energy-saving cutting equipment. It is an upgraded product of copy cutting machine and ordinary portable CNC cutting machine.

SKU: n/a$3,001.00 -

CNC Machines, Metal Machine Tool Industry

CNC cutting machine,Desktop 1530 plasma steel plate cutting machine, metal CNC cutting machine

CNC Machines, Metal Machine Tool Industry

CNC Machines, Metal Machine Tool IndustryCNC cutting machine,Desktop 1530 plasma steel plate cutting machine, metal CNC cutting machine

0 out of 5(0)The ambient temperature of the CNC cutting machine is 0°~50″, the ambient humidity is <90% without condensation, the surrounding environment is ventilated without large impact, the plasma power supply voltage is AC380V10%, the machine tool power supply voltage is AC220V10%, the power frequency is 50HZ/60HZ compressed air source pressure 08MPa, oxygen pressure 08MPa, gas pressure 01MPa

The equipment can be placed outdoors, and waterproof measures must be taken!SKU: n/a$10,033.00 -

Metal Machine Tool Industry, Sheet Metal Machines

New Electric Drill Plate Cutter,Metal Nibbler Drill Attachment with Adapter, DIY Metal Drill Attachment, Sheet Metal Knife for Cutting Iron, White Sheet, Steel,Copper, Aluminum(1PC)

Metal Machine Tool Industry, Sheet Metal Machines

Metal Machine Tool Industry, Sheet Metal MachinesNew Electric Drill Plate Cutter,Metal Nibbler Drill Attachment with Adapter, DIY Metal Drill Attachment, Sheet Metal Knife for Cutting Iron, White Sheet, Steel,Copper, Aluminum(1PC)

0 out of 5(0)- [Strong Cutting Ability] This metal nibbler drill attachment has a faster cutting speed than other sheet metal cutting tools, suitable for any drill bit working between 1500-3000, easier and more powerful than ordinary scissors and knives, it can save a lot of work time, Improve efficiency.

- [Electric Drill Plate Cutter Accessories] With a high hardness cutting head, this nibbler attachment can handle iron sheet(0.2-1mm), white sheet (0.3-1mm), steel sheet(0.2-0.8mm), copper sheet(0.3-1.2mm), aluminum sheet(0.3-1.2mm).

- [Easy to Use]: This metal cutter attachment quickly transforms your drill into an electric shear that fits perfectly on the chuck of your drill. And it also comes with an adapter handle, which can adapt to a variety of different electric drills. The drill bit is very compact, easy to store when not in use, perfect for your toolbox or locker and easy to carry.

- [Multi-purpose application]The metal nibbler drill attachment board cutting machine is suitable for cutting flat sheet metal less than 1mm. It can not cut sheet metal with blending, ribbed, special-shaped or welded shape or non-metallic material. It can not be cut forward if it gets stuck, set the drill to reverse for automatic exit.

- [Points to Note]We do not recommend cutting stainless steel and special high-hardness alloy materials, otherwise the machine will be damaged. If stainless steel must be cut, the thickness of stainless steel shall not exceed 0.5mm. And this drill is not suitable for cutting plastics

SKU: n/a$60.00 -

CNC Machines, Metal Machine Tool Industry

CUT70 new plasma cutting machine,110/220 dual power supply

0 out of 5(0)1. Wide current adjustment range, excellent adjustment characteristics, suitable for cutting carbon steel, stainless steel and other non-ferrous metals:

2. Double module design, high reliability;

3. Non-contact high-frequency arc ignition, high arc ignition success, stable transfer arc ignition, and low interference; 4. Fast cutting speed, small deformation, twice the speed of traditional oxygen acetyleneSKU: n/a$1,198.00

There are no reviews yet.