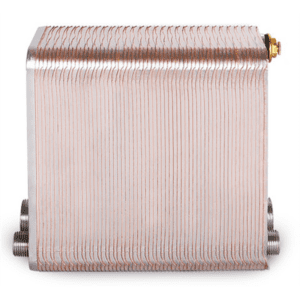

Innovative heat exchanger – Reduces emissions

Detachable plate heat exchanger

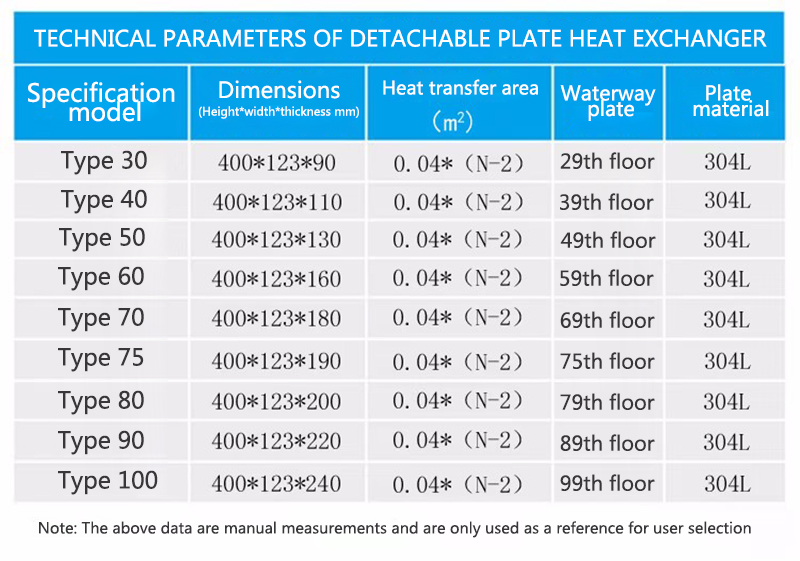

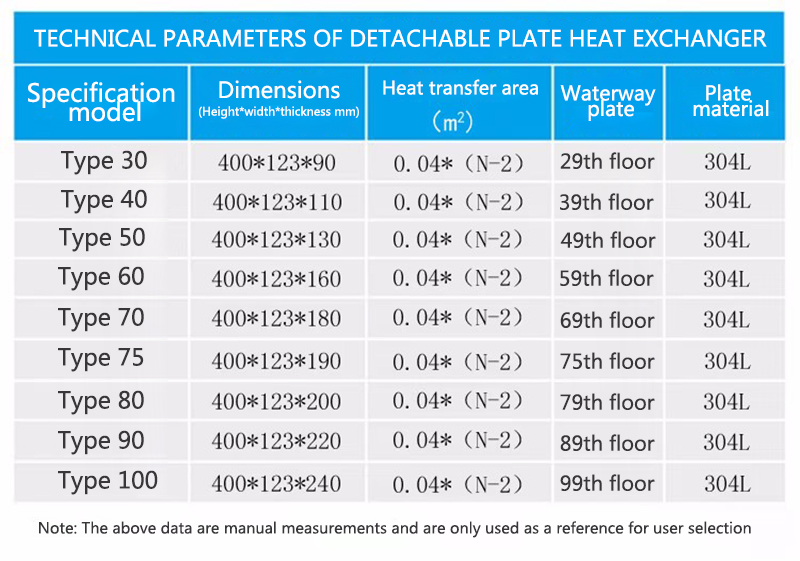

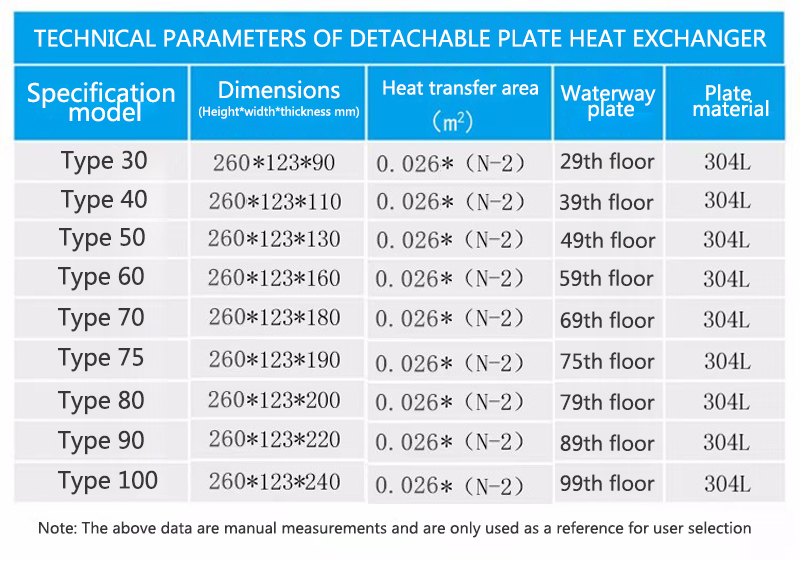

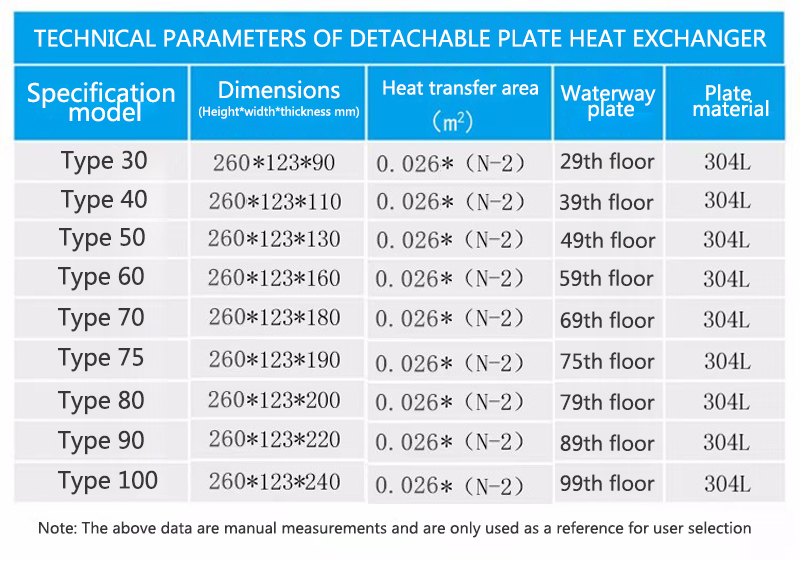

1.Model: Type 400 type 260 type

2.Guard plate material: low-carbon steel electrostatic spraying, stainless steel primary color

3.Plate material: SUS:304 (food grade stainless steel)

4.Plate thickness: 0.4mm-0.5mm

5.Standard accessories: expansion bolts, special wall-mounted pieces

$1,460.00

CompareReminder: Industrial models are customized products, please contact customer service before placing an order.

Industrial type plate heat exchangers are large and heavier commodities, and generally need to be picked up by customers after being shipped to the logistics site of the buyer’s city; (Note: This type is a large and heavier commodity, and the freight is higher!For returns and exchanges without product quality problems, the round-trip freight must be taken care of by the customer. Visa refusal is not supported after delivery, please understand!)

Commercial models are relatively light, and express delivery is available in most areas. You can consult customer service after taking the photo.

Advanges of Plate Heat Exchangers

Easy to Remove and Clean

- Plate Heat Exchangers are easy to clean by remove the tie bolts and slide back the movable frame part. Then the plate pack can be inspected, pressure cleaned, or removed for refurbishment if required.

Expandable

- A very significant feature of the plate Heat Exchanger is that it is expandable. Increasing the Heat Transfer requirements means simply adding plates instead of buying a new Heat Exchanger, saving time and money.

High Efficiency

- Because of the pressed patterns in the plates and the relative narrow gaps, very high turbulence is achieved at relative low fluid velocity. This combined with counter directional flow results in very high Heat Transfer coefficients.

Compact Size

- As a result of the high efficiency, less Heat Transfer area is required, resulting in a much smaller Heat Exchanger than would be needed for the same duty using other types of Heat Exchangers. Typically a plate Heat Exchanger requires between 20-40% of the space required by a tube and shell Heat Exchanger.

Close Approach Temperature

- The same features that give the plate Heat Exchanger its high efficiency also makes it possible to reach close approach temperatures which is particularly important in heat recovery and regeneration applications. Approach temperatures of 0.5°C is possible.

Multiple Duties in a Single Unit

- The plate Heat Exchanger can be built in sections, separated with simple divider plates or more complicated divider frames with additional connections. This makes it possible to heat, regenerate, and cool a fluid in one Heat Exchanger or heat or cool multiple fluids with the same cooling or heating source.

Less Fouling

- Very high turbulence is achieved as a result of the pattern of the plates, the many contact points, and the narrow gap between the plates. This combined with the smooth plate surface reduces fouling considerably compared to other types of Heat Exchangers.

Lower Costs

- High Heat Transfer coefficients mean less Heat Transfer area and smaller Heat Exchangers, and sometimes even less Heat Exchanger.

| Weight | 20.0 kg |

|---|---|

| brand | ndpac |

There are no reviews yet.